Improving Scratch Resistance and Durability of Deep Matte Plastic Coatings

Blue Planet Studio / Creatas Video+ via Getty Images Plus

Plastics are increasingly used as a construction material for many different applications, including consumer electronics, automotive parts and components, and packaging. When compared with other materials, plastics can be lighter in weight, easier to manufacture and mold into different shapes and forms, and may also offer lower raw material costs and improved chemical or corrosion resistance. The term plastic is a generic term used to describe many different polymers with widely varying chemical compositions, and physical and mechanical properties.¹ However, the surfaces of many plastics have poor resistance to scratching and abrasion, so these are often coated to improve their resistance to surface damage and improve long-term durability.

Coatings are used to protect, enhance the appearance and even functionalize the surface of the plastic substrate. However, during their service, coatings are often exposed to physical contact with other hard surfaces, such as fingernails, keys, washing brushes and other objects that can leave damage or marks on the coating surface.² These defects can be very visible in matte and deep matte finishes where the marks created by the abrasion can be higher gloss and very visible against the rest of the undamaged coating. Formulators therefore continue to seek new ways to improve the scratch and abrasion resistance of these coatings to enhance their long-term durability and aesthetics.

Scratch resistance of a coating and coated substrate is a complex subject that can be affected by multiple factors, including the test method, forces applied, the nature of the abrasive material as well as the coating formulation.³ The type of damage created by different scratch and abrasion tests also varies by method, causing removal or displacement of the localized coating film as well as cracking and micro-cracking.⁴ Therefore, different test methods may be needed to assess the scratch and abrasion resistance of a coating and coated substrate.

Experimental

A series of matting agents with different particle sizes and chemistries was selected for the study. A full list of the products studied is shown in Table 1. These varied in particle size (d50, µm), oil absorption (DOA, mL/100 g), surface area (BET, m²/g), melting point (°C) and density (g/cm³); all the values reported are taken from the product literature, so the test methods used for the measurements may vary.

Each product was tested in the three different solvent-based (SB) coatings. The first formulation was a black baking enamel, Duplex D1326 supplied by Axalta. The second formulation was a clear or black pigmented, two-component (2K), polyurethane (PU) solvent-based coating based on a formulation from Covestro; the formulation, preparation and application methods are shown in Table 2. The third formulation was a soft-feel coating, also based on a 2K SB PU formulation from Covestro, shown in Table 3.

The first two formulations were spray applied onto black acrylonitrile butadiene styrene (ABS) plastic panels using an ANEST IWATA W-71 spray gun with an air pressure of 0.4 MPa; the wet film was flash dried for 1 to 3 minutes at room temperature before curing at 80 °C for 30 minutes in a ventilated oven. The dry film thickness of the cured coating was 16 to 20 µm.

The third formulation (soft touch) was spray applied onto black ABS panels using an ANEST IWATA W-71 spray gun with an air pressure of 0.2 MPa; the wet film was flash dried for 10 minutes at room temperature before curing at 80 °C for 120 minutes in a ventilated oven. The dry film thickness of the cured coating was approximately 40 µm.

The rheology of the liquid coatings was recorded using Thermo equipment model Haake RotoVisco 1 rheometer, and the fineness of grind measured with a TIDAS Automated Grindometer from Labman Automation. The gloss of all the cured coatings was measured using a BYK Gardner Haze-gloss meter, model 4601, and film transparency measured with an X-Rite model SpectroEye. The surface roughness of the cured coatings was measured using a Hommel Etamic Waveline W5 instrument.

The scratch resistance of the cured coatings was measured using a BGD 525 Linear Rubbing and Alcohol Abraser from Biuged Laboratory Instruments (Guangzhou) Co. Ltd. with 3M 281Q Wet or Dry polishing paper on a 1 cm² area of coating. Two test methods were used: the first used 500 g/cm² pressure for 100 double rubs and the second used 140 g/cm² pressure for 10 double rubs.

The abrasion resistance of the coating was measured using a 7-IBB-CC RCA Abrasion Wear Tester from Norman Tool, Test Equipment and Supplies, used for testing painted or plated organic finishes for the automotive, appliance, cell phone, plastics and coating industries. It uses an inexpensive roll of throwaway abrasion paper as the abrasive material. A 175 g weight was used on the coating surface, and testing continued until the ABS substrate was exposed (Figure 1).

Results

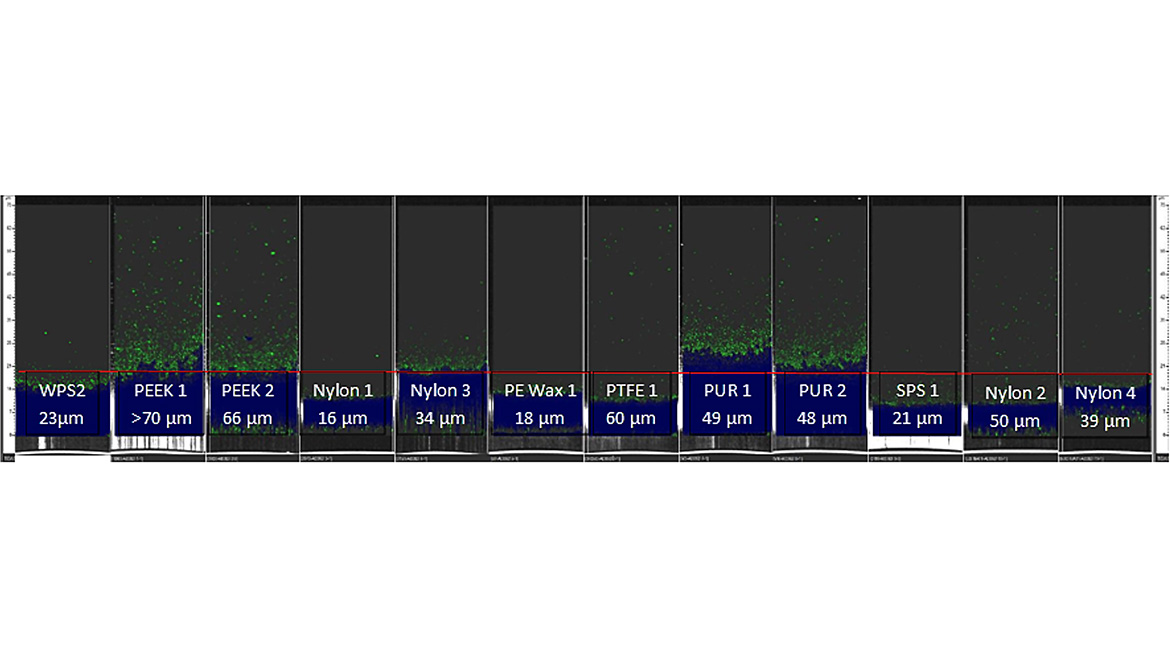

The different matting agents were first tested for matting efficiency in the Duplex D1326 black baking enamel from Axalta. The Duplex D1326 was diluted 100:20 with the supplied V0003 thinner, and 5.5 g of matting agent was added to the diluted coating and mixed in with a 45 mm diameter blade stirrer for 10 minutes at 2,000 RPM. The matted coating was then stored in a closed beaker for 30 minutes to allow for deaeration. The coating was then applied with an Erichsen Coatmaster 509 MC onto 3 mm glass plates using a 120 µm doctor blade applied at a speed of 25 mm/s before it was allowed to evaporate for 10 to 20 minutes under ambient conditions and then cured for 20 minutes at 150 °C. The dispersibility and fineness of grind of the matting agent into the coating was measured using a Labman TIDAS Automated Grindometer, and the results are shown in Figure 2.

The liquid coating was also allowed to stand for 7 days under ambient conditions to observe how the different matting agents settled on storage. The surface appearance of the coatings is shown in Figure 3, and the gloss, roughness and settling results are shown in Table 4.

A summary of these results is shown in Table 5. The results clearly show the much greater matting efficiency of the precipitated silica matting agent, WPS2, in this formulation. The spherical silica particles were less effective for matting and showed significant settling, a result also seen with this material when used in water-based wood coatings.⁵ The organic matting agents evaluated were less effective in the formulation and some were difficult to disperse effectively. Many were also prone to settling on storage, although this was soft settling that could be stirred back into the coating. The larger size nylon particles, 3 and 4, showed greater matting than the smaller nylon particles as expected,⁶ but also gave surface defects like mottling and pinholes.

The matting agents were tested again in the solventborne clear coat formulation from Covestro, shown in Table 2. The use level of the matting agents was 5.5% by weight of total formulation to achieve the target of ≤ 5 gloss units at 60°. The four precipitated silica matting agents tested all achieved the target gloss levels, as did the PUR 1 matting agent (Figure 4). The two PEEK matting agents were more effective in this formulation, although they could not achieve the desired level of matting (gloss reduction) at the tested use level. The larger nylon matting agents were again more effective than the smaller nylon samples, and the two waxes tested were not effective. The matting efficiency correlated reasonably well with increasing surface roughness of the dry coating film.

All the matting agents caused some thickening, increasing both low- and high-shear viscosity, except for the polyethylene wax (PE Wax 1). The effect on rheology was mostly chemistry dependent, with all the PEEK and nylon matting agents causing similar effects. The untreated precipitated silica (PS1) had a larger impact on rheology than the surface-treated silicas. Some matting agents also affected the coating film transparency, with the silica- and polyurethane-based additives causing some film whitening.

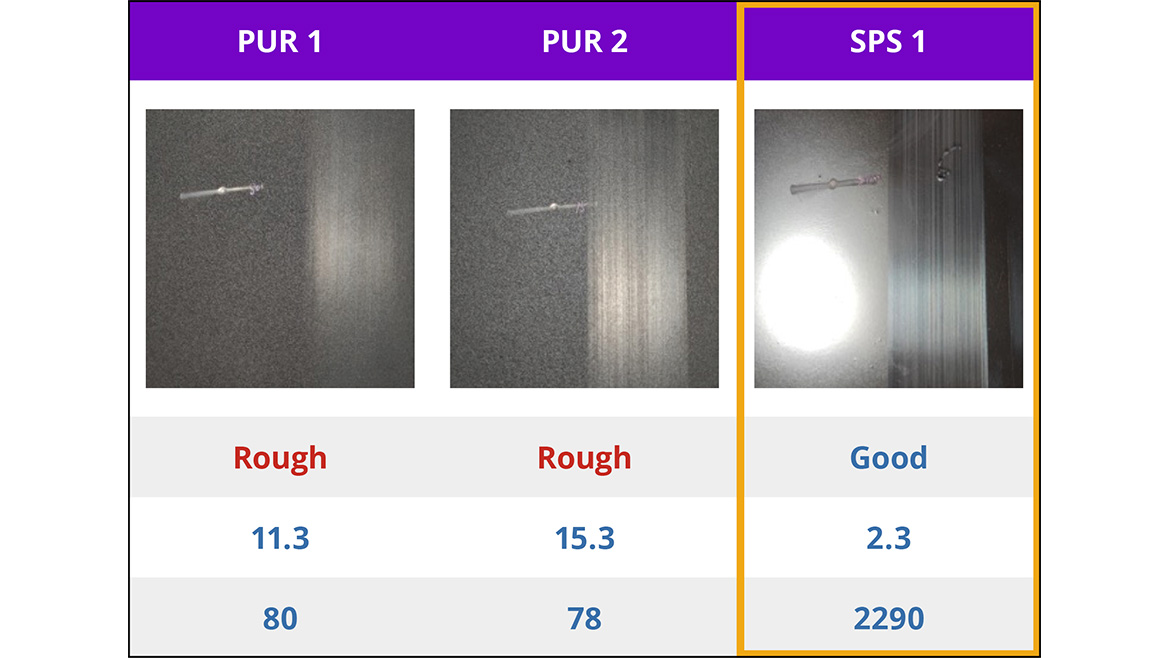

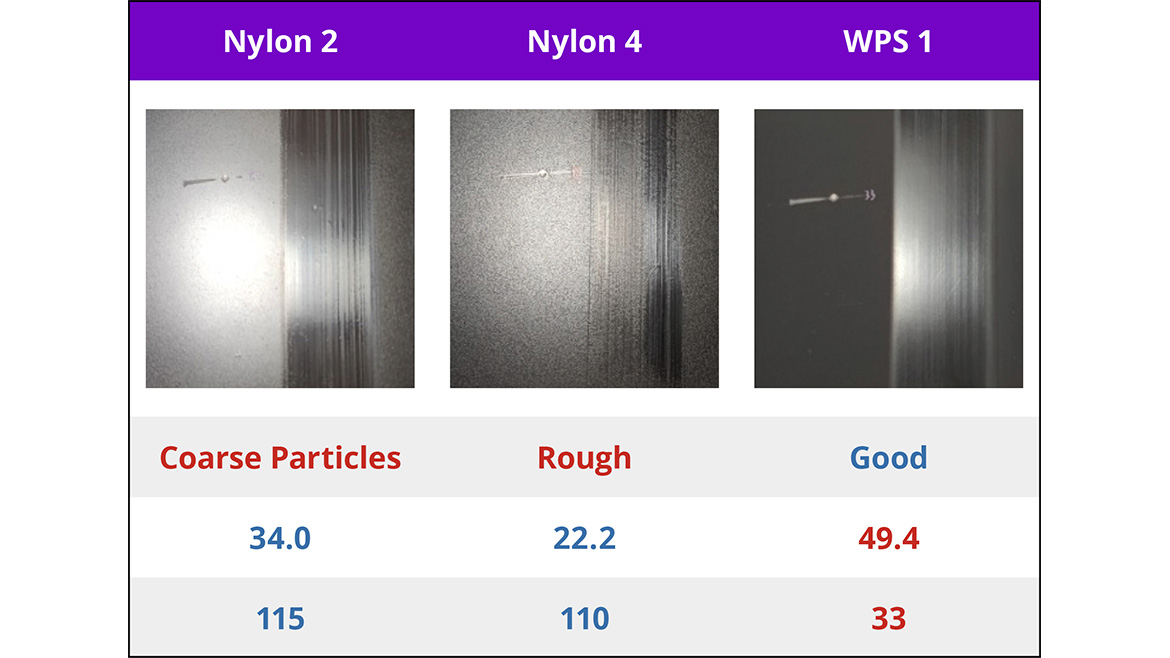

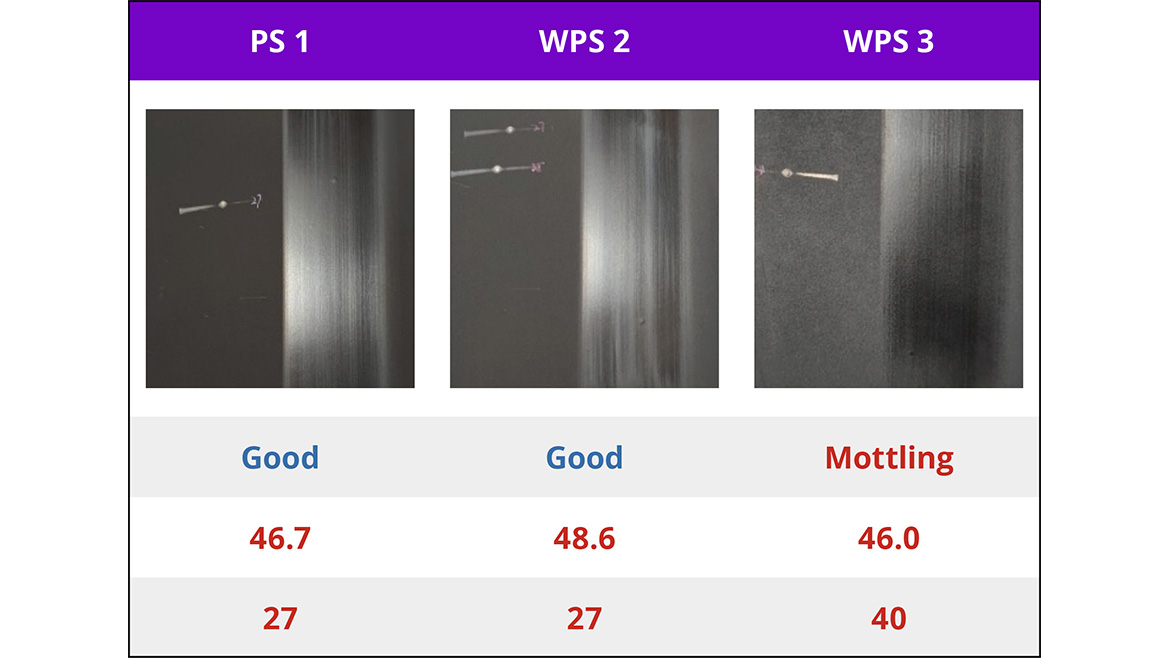

The applied coatings were then evaluated for scratch and abrasion resistance. The results with the BGD 525 Abraser were measured by the change of gloss in the coating after testing. All the coatings showed significant up-glossing and none of the matting agents was able to maintain the target gloss level below 5 gloss units after testing. This effect was most pronounced with the traditional precipitated silica matting agents, although these also gave the lowest initial gloss levels. The polyurethane-based matting agents maintained the lowest gloss levels during this test, while the PTFE Wax (PTFE 1) and spherical precipitated silica showed the most resistance to burnishing. Most of the matting agents also slightly improved the resistance to the RCA Abrasion Wear Tester, with the two wax additives (PTFE 1 and PE Wax 1) having the best effect. However, the spherical precipitated silica (SPS1) dramatically improved the resistance of the coated film by an order of magnitude. These results are shown in Figure 5. Most of the matting agents tested also reduced the film resistance to a 6 N scratch test using the Taber Five Finger Scratch Tester. SPS1, PTFE 1 and PE Wax 1, together with Nylon 1 and 2, had maintained the best scratch resistance in this test.

These results are summarized in Table 6, which also includes a summary of some additional chemical resistance testing. The silica matting agents were the only products capable of achieving the target level of matting (60° gloss less than 5 gloss units), but these have poor scratch and abrasion resistance. The polymethyl urea resin additives (PUR 1 and particularly the larger PUR 2) also gave low gloss values, but a rough surface effect, and these also gave limited abrasion resistance. The wax additives (PTFE 1 and PE Wax 1) improved scratch resistance and helped abrasion resistance. The spherical precipitated silica had the greatest effect on improving abrasion resistance.

A series of additive combinations were studied to determine whether combinations could achieve the goal of low gloss with good surface appearance with improved scratch and abrasion resistance. The studies focused on combinations of precipitated silica with the wax additives, two of the nylon additives and the spherical precipitated silica. The combined additive loading in the formulation was adjusted to achieve a deep matte finish with a 60° gloss around 1.5 gloss units. These coatings were then tested for scratch resistance using the first method with the BGD 525 Abraser and RCA abrasion resistance. The results are shown in Figure 6.

A combination of traditional precipitated silica with the spherical precipitated silica gives a deep matte coating with excellent abrasion resistance, although it is still prone to burnishing by the Abraser method. The Nylon 1 and PE Wax were the most effective at reducing the burnishing. However, the total amount of additive needed was quite high, so further tests were made to understand the effect of different additive loading using different combinations of WPS1 with either Nylon 1, SPS1 and PE Wax 1 at a total loading of 5.5% additive. These results are shown in Figure 7.

The PE Wax 1 was much more effective than the Nylon 1 at the lower use level for maintaining low gloss and preventing burnishing via the Abraser method. A 1:3 ratio of wax to silica gave the best overall performance. Increasing the ratio of SPS1 improves the abrasion resistance of WPS1 in the matted coating, as expected, but higher levels of WPS would be needed to achieve the required level of matting. Further studies showed that about 3.5% SPS1 was needed to significantly improve the abrasion resistance, and this combination also gave the best results in the 6 N Five Finger Scratch Test.

These results are like those seen in wood coatings⁵ and architectural coatings⁷ where larger-sized spherical precipitated silica particles were used. However, when the larger particles were tested in this formulation, they gave a rough and inconsistent film surface although abrasion resistance was improved, suggesting that the particle size of the spherical silica additive should be matched to the size of the matting agent and coating dry film thickness.

A similar study was conducted using the soft-touch coating formulation shown in Table 3. The coating was applied at approximately 45 µm dry film thickness, so a larger size precipitated silica, WPS2, was used for matting. This formulation was much less sensitive to the Abraser scratch test, but the SPS1 did improve the RCA abrasion resistance. These results are shown in Table 7. Unfortunately, SPS1 particles reduced the resistance of the coating to the 6 N scratch test in this formulation.

Conclusions

Conventional silica-type matting agents like WPS1, WPS2 and PS1 are easily dispersed and provide good matting and surface appearance, but poor scratch and abrasion resistance in the plastic coatings tested. Organic matting agents have better scratch and abrasion resistance but are less effective for matting and many had poor dispersibility and surface appearance in the systems tested.

The best results were obtained with PE Wax 1 and Nylon 1 that had good dispersibility and surface smoothness.

The spherical-shaped precipitated silica particles, SPS1, was poor at matting in these formulations, but highly effective at improving abrasion resistance, although high dosage may be required. Combinations of these particles with wax-treated silica matting agents could dramatically improve the abrasion resistance without side effects. Combinations of wax-treated silica and small-size nylon powders or PE waxes could also improve the surface scratch resistance without side effects, and the PE Wax was more efficient than the nylon at different gloss levels.

Acknowledgements

The authors would like to thank Dr. Ali Javadi, Nick Price and Paul Marcella for their help with the Taber Scratch tests and to also thank Dr. Ingrid Meier and Francisco Cortes-Baledon for editorial support.

References

1 An Introduction to Plastics. ChemicalSafetyFacts.org. https://www.chemicalsafetyfacts.org/chemistry-101/an-introduction-to-plastics/ (accessed 2024).

2 Ryntz, R. A.; Abell, B. D.; Pollano, G. M.; Nguyen, L. H.; Chen, W. C. Scratch Resistance Behavior of Model Coating Systems. J. CoatingsTech 1999, 72 (904), 47–53.

3 Smeets, S. Evaluation of Scratch Resistance Test Methods for Organic Coatings. Paint and Coatings Industry Magazine 2004, March.

4 Seubert, C.; Nietering, K.; Nichols, M.; Wyckoff, R.; Bollin, S. An Overview of the Scratch Resistance of Automotive Coatings: Exterior Clearcoats and Polycarbonate Hardcoats. Coatings 2012, 2, 221–234.

5 Semmler, H.; Schuster, P.; Meier, I. K. Novel Silica Particle Technology for High Durability Matte Wood Coatings. Coatings World 2023, July.

6 Evonik. Acematt® Matting Agents for the Coatings Industry; Technical Bulletin #21, 2016; p 13.

7 Meier, I. K.; Hazim, T. New Tools for Improving the Durability and Maintaining the Appearance of Architectural Coatings. Paint and Coatings Industry Magazine 2022, September.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!