Optimizing Effect Paint Formulation with Smart Technology

With growing demands for efficiency, sustainability and customization in automotive, industrial and consumer applications, achieving accurate and repeatable color formulation has become more critical than ever. Smart technology is transforming industries worldwide, and the paint and coatings sector is no exception. Smart technology refers to devices, systems or technologies that use advanced software, sensors and connectivity to collect data, analyze it, and make decisions or adapt based on that data. These technologies are designed to be intuitive, efficient and often operate autonomously, improving user experience, automation and functionality.

Traditional methods for effect paint color formulation are time-consuming and costly, often requiring 10 or more iterations to achieve the desired match. The emergence of smart formulation software is changing that by optimizing pigment selection, reducing waste and enabling faster, more precise color development.

The Complexity of Effect Paint Color Formulation

Effect paints, such as metallics and pearlescents, continue to gain popularity, particularly in the automotive market. These coatings create visually striking finishes and cater to consumer demand for personalized and premium aesthetics.

However, formulating effect paints is more complex than standard colors due to the way light interacts with pigments, binders and substrates. Unlike solid colors, effect paints exhibit characteristics such as sparkle, coarseness and color shifts that vary with viewing angles and lighting conditions. Capturing and matching these properties requires color measurement and formulation tools that can analyze spectral and appearance data to ensure an accurate representation of the final appearance.

Environmental and regulatory considerations add further complexity. Many traditional pigments contain heavy metals or other substances being phased out due to environmental concerns. Reformulating existing colors with new, eco-friendly pigments while maintaining the same optical properties demands sophisticated software and smart algorithms to accelerate recipe development.

Color Matching Effect Paints

The primary goal of color matching is to find a recipe that matches the appearance of a target sample when applied to a specific substrate. This process is particularly challenging for effect paints, which require matching not just color but also texture and other visual effects.

Traditionally, this requires highly skilled professionals and involves significant trial and error. In the automotive refinish market, for example, up to 80% of a paint manufacturer's R&D budget is allocated to color matching, with some formulations requiring as many as 15 iterations.

How Software Enhances Color Matching

Software-assisted color matching streamlines this process by reducing the number of iterations needed and accelerating each step. Two main approaches are:

- Search and correct – In this method, the process begins with a multiangle measurement of the target sample. The software searches a database of known recipes and corresponding measurements to find the closest match. Even the best match often requires adjustments, but these refinements are relatively minor, making this approach efficient — provided a suitable database exists. Without such a database, however, the method is ineffective.

- Formulation from scratch – When no suitable database of recipes exists, a new formulation must be created from the ground up. This is significantly more complex and requires sophisticated physical models to predict pigment interactions under various conditions.

Effect paints demand advanced multiflux models to simulate how photons interact with layered materials. Traditional models like Kubelka-Munk work well for many applications but — due to simplified assumptions and equations — fall short for effect paints, necessitating more advanced physical models.

Historically, the complexity of formulating effect paints from scratch has limited the use of this approach. However, modern cloud computing architecture together with smart algorithms are changing that by making full-scale formulation more practical and efficient.

A typical "formulation from scratch" workflow follows these steps:

- Measurement of target sample – Multiangle spectrophotometers capture spectral and texture data.

- Pigment pre-selection – Users select pigments likely to produce the desired effect, reducing computational complexity.

- Rule definition – Users select constraints such as pigment compatibility and regulatory compliance.

- Combination evaluation – The software determines valid pigment combinations based on pre-selection and constraints.

- Optimization – Optimal pigment amounts that maximize multiangle spectral similarity are computed in a highly parallelized optimization process, leveraging the power of cloud computing.

- User review and selection – Users review and select the best formulation for production.

Automatic Pigment Selection

Selecting the right pigments is one of the most challenging steps in the formulation process, requiring extensive experience and detailed analysis of the target sample. Devices like the X-Rite MA-T12 enhance this process by capturing spectral data at multiple angles and providing calibrated HDR color images, which convey far more information than reflectance alone. This information can be used to derive specific metrics that describe paint properties — such as coarseness and sparkle grade — or fed into machine learning models like convolutional neural networks (CNNs) to predict optimal pigment combinations.

Data-driven approaches, also in combination with AI, can streamline pigment selection, eliminating unsuitable options and identifying the most viable candidates. Machine learning analyzes spectral data, identifies patterns in color behavior and enables automatic pigment selection, minimizing the need for manual adjustments.

Role of Parallel Computing and Cloud Solutions

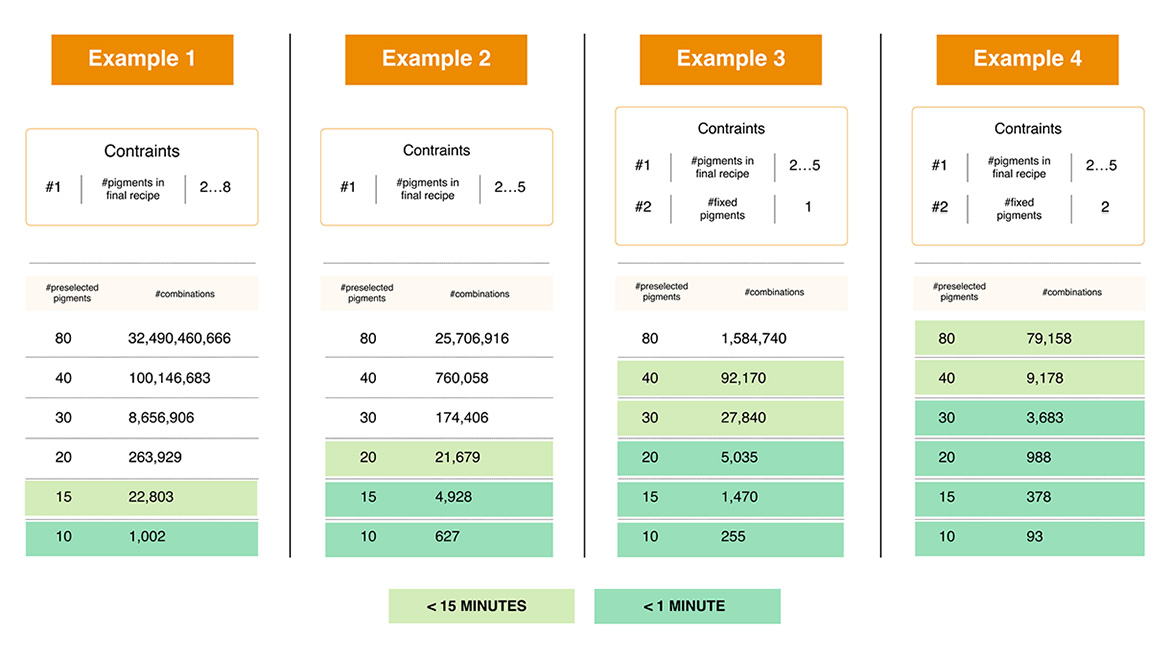

Formulating an effect paint color from scratch is computationally intensive due to the vast number of potential pigment combinations. Without proper constraints, a single formulation request can involve millions of possibilities, each involving a full optimization process, making traditional software approaches slow.

Parallel computing makes this approach feasible. Instead of sequentially evaluating pigment combinations, parallel systems process multiple possibilities simultaneously. In contrast to traditional server-based setups, cloud computing enables quickly scaling resources up or down to meet business demands without having to invest in physical infrastructure. It therefore handles peak loads much more efficiently and with less cost. As an example, our current implementation utilizes 100 nodes in parallel and on average computes about 100 combinations per second, translating to 6,000 evaluated combinations per minute — independent of the number of simultaneous formulation requests. Together with suitable constraints, this scalability easily reduces the computation time from hours to minutes or even seconds.

Platforms like AWS provide flexible resources that enable multiple users to run formulations simultaneously without performance slowdowns.

Industry Impact and Key Benefits

Smart effect paint formulation tools developed by X-Rite already deliver tangible benefits, reducing the number of required formula iterations from 8–12 down to just 2–4. Moreover, the first formulation attempt achieves an accuracy of ΔE 3–3.5, which is a significant improvement over traditional methods.

By minimizing the number of required iterations and accelerating each step, smart software solutions lead to:

- Reduced material waste – Less pigment and binder consumption per cycle.

- Faster time to market – Shortened R&D timelines for new color development.

- Lower costs – Reduced labor and operational expenses through automation.

- Improved sustainability – Optimized raw material use aligns with eco-friendly practices.

- Enhanced quality control – AI ensures color consistency across production batches.

The Future of Smart Technology in Paint Formulation

The integration of smart technology and parallel computing into effect paint color formulation represents a major advancement for the coatings industry. The rich information provided by modern multiangle spectrophotometers such as X-Rite’s MA-T12 also lends itself to leveraging the power of AI. As AI models continue to evolve and incorporate more data, they will further refine the formulation process, enabling manufacturers to achieve unprecedented levels of accuracy while reducing waste and costs. In an industry where precision and efficiency are paramount, smart solutions are set to transform effect paint color formulation.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!