Powder Coating Nonconductive Substrates

Image credit: cgtoolbox / Creatas Video via Getty Images.

Powder coating is traditionally applied electrostatically to a conductive (typically metal) substrate. The charged particles are attracted to the grounded object and uniformly deposited on the surface. However, as low-temperature-cure powder coatings become more available, the possibility of using them for coating a wide variety of heat-sensitive and nonconductive substrates is more of a reality than ever before.

It is possible to apply a powder coating to a nonconductive substrate in many ways. Common methods include hot flocking, thermal spray, in-mold coating, and the use of conductive materials and processes.

Hot Flocking

Hot flocking is the process of preheating the substrate and applying the powder while it is still hot. This method works especially well with substrates like glass that are not conductive but can withstand higher temperatures. It does not work well with substrates like injection-molded plastics that deform at low temperatures and shed excess heat quickly. With hot flocking, an applicator must also be wary of film thickness, as it is easy to apply more than intended to a hot part.

A preheating process can be successfully employed for certain substrates like MDF (medium-density fiberboard). MDF has a moisture content such that a short period of heating the surface will draw out a small amount of water, enough to make the surface conductive and amenable to electrostatic powder deposition.

Thermal Spray

In a thermal spray process, the powder passes through a heat source like a flame or plasma and melts in the air before it reaches the surface to be coated. This method is well-suited to thermoplastic powders that do not need to be held at a constant temperature for a period of time to crosslink like most thermoset powder coatings. While film thickness is also difficult to control, thermal spray may be a viable option for end uses where a thick coating is preferred (e.g., large outdoor fixtures).

In-Mold Coating

During in-mold coating, the coating is sprayed on the inside of a mold before the substrate material is introduced and formed. The heat and pressure help to cure the powder and ensure excellent adhesion to the substrate.

This process can be used with a sheet molding compound, fiber-reinforced plastic, prepreg composite type construction or possibly even with injection-molded parts. When using this method, coatings that outgas (e.g., hydroxyalkylamide-cured polyesters and epsilon caprolactam-blocked isocyanates) must be avoided. Since there is nowhere for the volatiles of cure to escape, film defects will result.

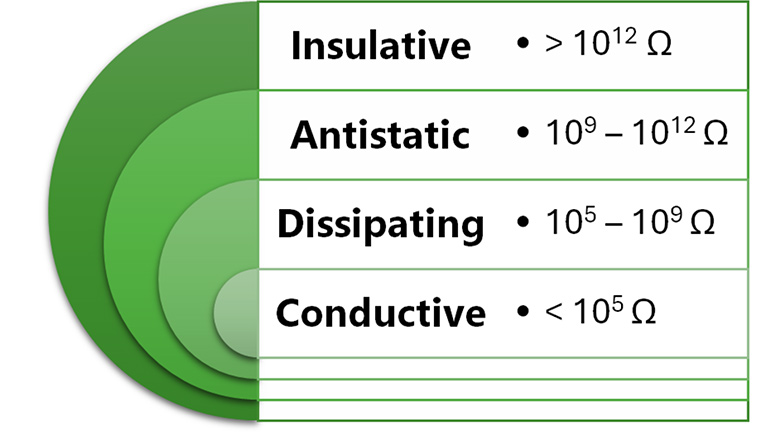

Embedded Conductive Materials

Conductive materials such as carbon black, graphene or carbon nanotubes can be compounded into a plastic or composite substrate. This can potentially make the substrate behave just like steel or aluminum in the electrostatic application process.

One downside of this approach is that the conductive material is distributed throughout the bulk of the part and can add unnecessary cost to the material. The addition of conductive materials to the substrate can also potentially have a negative effect on the material’s mechanical properties.

Conductive Primers

A conductive primer is a traditional water- or solventborne liquid paint that contains conductive components. The surface of the part is first coated with the liquid paint. After it’s allowed to cure, the part will have a conductive surface favorable to electrostatic powder application.

This approach may render the layer of powder coating unnecessary; if the coater is already applying a coat of paint, the powder coat may not provide additional benefit. A use case where a conductive primer paint comes in handy is when a coater would like to create a splatter effect that is not normally possible with powder coating alone.

Conductive Pretreatments

Finally, a conductive solution is a nonpermanent surface treatment step that can be applied to the surface of a part to impart sufficient conductivity for electrostatic spray application. Since the technology was originally developed by Ransburg Corp., it is not unusual for the material to be referred to as Ransprep (though the trade name is no longer in use).

The technology comprises quaternary ammonium salts, diluted at a concentration of 1–10% in a polar solvent such as water or isopropyl alcohol. The solution is applied by spray or dip, and the carrier is flashed off. The remaining layer is hydrophilic and attracts ambient moisture to form an electrolyte on the surface. For this reason, inadequate humidity in the air could render the conductive solution less effective.

The downside is that this process introduces a liquid spray step that is normally not required for powder coating application. Water requires time and energy to effectively evaporate, and solvents like alcohol or acetone may be considered volatile organic compounds (eroding the typically environmentally beneficial attributes of a powder coating finishing operation). Under the correct conditions, though, this approach to introducing conductivity makes it possible to powder coat all manner of substrates that were previously impossible.

Expanding Opportunities

Gone are the days of “if it’s made of metal and fits in an oven, you can powder coat it.” These methods of coating nonconductive substrates, combined with low-temperature-cure technology, open up a wide world of new markets and opportunities for the powder coating industry.

To learn more, contact the author at nbiller@chemquest.com or visit https://chemquest.com/cqpcr.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!