3D Color Visibility Label for Mobility Coatings

Enhancing Traffic Safety Through Color and Sensor Perception

As the transportation and mobility industries transition toward autonomous vehicles, a core challenge remains: reliably measuring and ensuring vehicle visibility across varying and dynamic traffic environments. Despite advances in computer vision and LiDAR systems, a lack of universal standards for visibility, particularly regarding color and the complexities of three-dimensional vehicles, limits regulatory progress and leaves safety risks unresolved. Traditional approaches, like lights and reflectors, focus on specific visibility points but overlook the bigger goal: full surface and form detectability of complex vehicle shapes.

The Role of Color and Shape in Visibility

Visibility, defined as the capacity for a vehicle to be effectively detected by humans and machine observers, is linked not just to technological equipment but also fundamentally to the color and shape of the object. Studies involving over 850,000 traffic incidents¹ illustrate a statistically significant connection between car color and crash risk, with white coatings showing the highest visibility and lowest crash rates. However, industry data reveals that color classifications are often too broad, overlooking important distinctions within color groups and the impact of shape on visibility under low-light conditions.

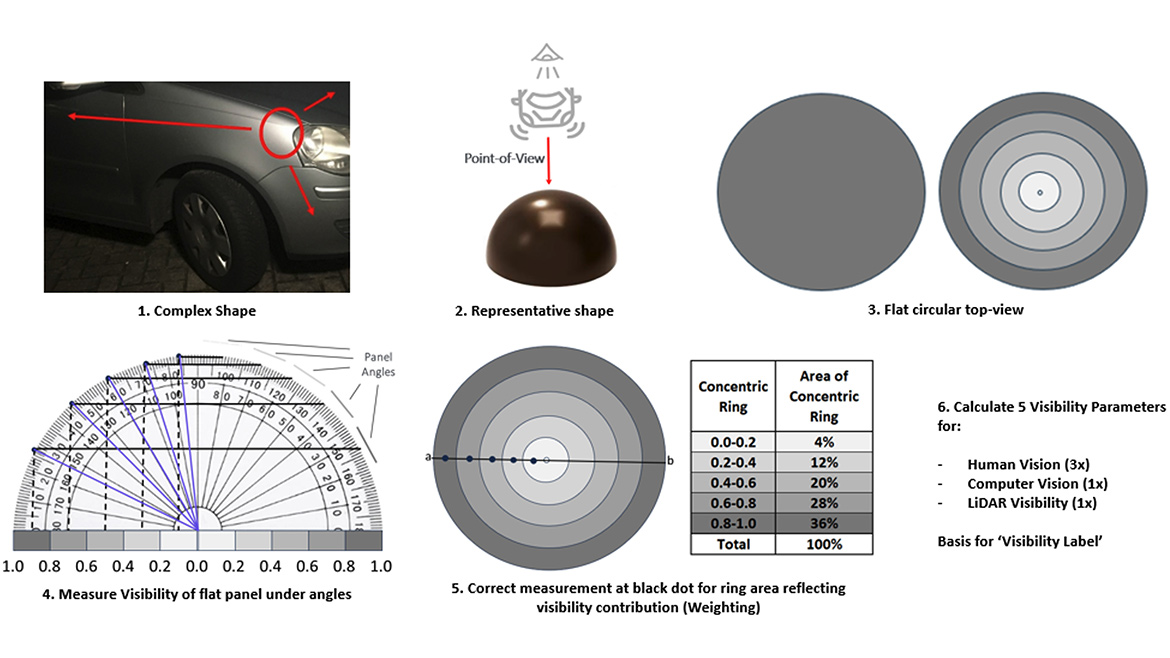

Vehicle shape adds to this complexity. Most visible surfaces are curved, causing angular-dependent point-of-view (AIPOV) visibility², where colored coatings reflect and scatter light differently depending on the observed angles. Empirical studies confirm that LiDAR reflectivity sharply decreases at higher incident angles, highlighting the importance of considering both object geometry and coating color composition in visibility models.

Existing Solutions and Standards

Current safety regulations focus on lights, reflectors, and, for certain emergency vehicles, highly visible colored stickering and paints. Advanced driver assistance systems (ADAS), like computer vision and LiDAR, have improved detection but lack standardized metrics for evaluating color visibility across three-dimensional vehicle surfaces. ISO 19206 and the Global Vehicle Target (GVT) standards address some aspects of sensor detectability but have not yet delivered comprehensive frameworks for color and curved surface visibility assessment for LiDAR and Camera Vision modalities.

In industry response, manufacturers are experimenting with new pigment technologies to provide sensor-friendly colors, including near-infrared (NIR) transparent and reflective pigments and emerging crystal glass pigment (CGP) formulations. Still, most approaches focus only on perpendicular (flat) surfaces, leaving the visibility of 99% of real-world curved surfaces unaddressed.

The 3D Point-of-View Visibility Model

To bridge these gaps, a 3D PoV color visibility model was developed³. The model simplifies real-world vehicle shapes into a representative shape and quantifiable semi-spherical geometry. A small part of the object is perpendicular to the observer, while 99% is curved away. This geometrical shape enables direct measurement and calculation of visibility from any observer’s point of view (human, camera, or LiDAR). Instead of relying solely on flat-panel perpendicular color tests, the model divides the semi-sphere’s observed area into five concentric rings of equal width, corresponding to different surface angles on the semi-sphere.

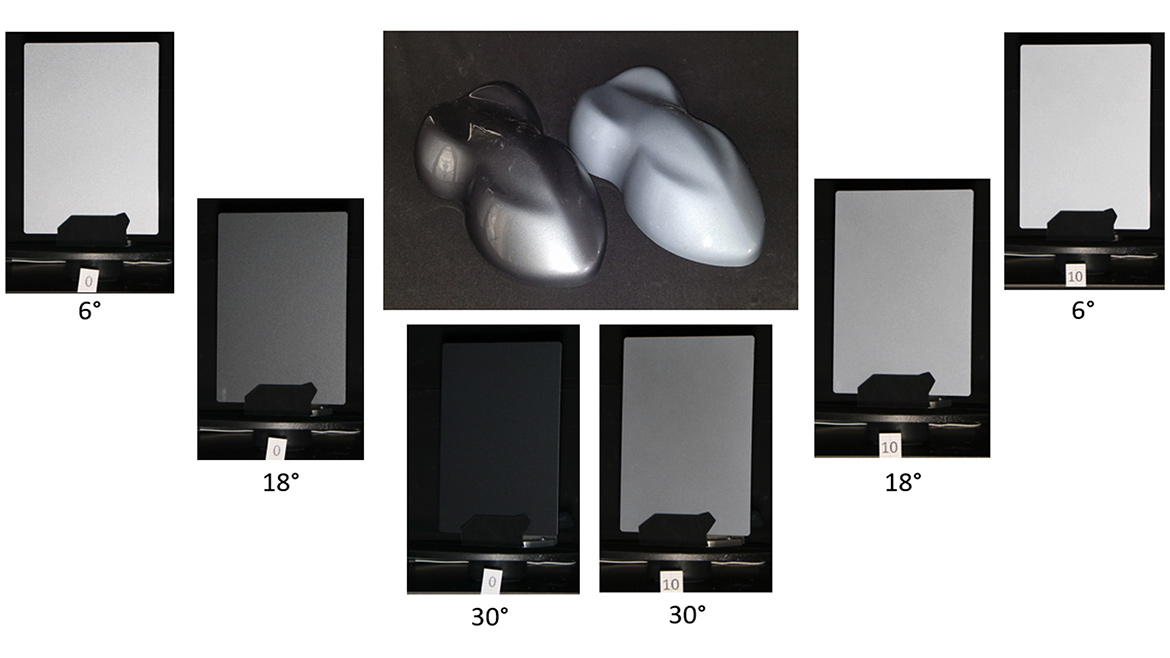

Visibility data is collected at five tangential angles (6°, 18°, 30°, 44° and 64°) using controlled lighting setups and standard measurement protocols. For each ring, reflectivity and luminance are measured, weighted by ring-surface area, and aggregated. This approach captures both the variation in color visibility due to angle and the contribution of the surface areas at larger angles, which are critical for understanding the environment under low-light conditions.

Measuring Modalities: Human Vision, Computer Vision and LiDAR

The model encompasses three major detection modalities:

- Human Vision: Assessed with Adrian’s Model (CIE), using relative luminance and contrast sensitivity, under two standardized lighting conditions (100 lux – dark overcast day, and 3 lux – end of civil twilight).

- Computer Vision: RGB average values measured by the camera, capturing visibility without subjective human color sensitivity.

- LiDAR Reflectivity: Intensity values, capturing sensor response irrespective of visible light conditions.

A mobility coating is then characterized by its performance across these modalities, accounting for the lighting situation and angular dependence.

The 3D Color Visibility Label and Parameters

The proposed visibility label comprises five independent parameters:

- Human visibility (100 lux)

- Computer vision (average of 100 and 3 lux)

- LiDAR visibility

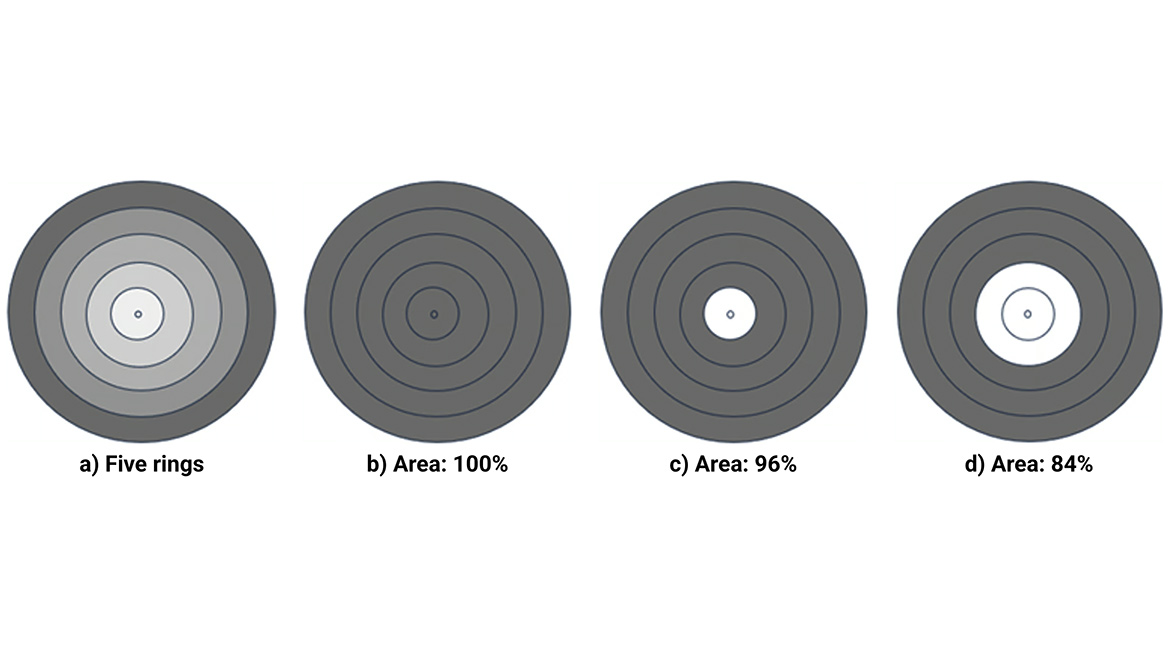

- Full object visibility (average human visibility of three outer rings, representing 84% of surface area, at an average of 100 and 3 lux)

- Twilight visibility (average human visibility of four outer rings, representing 96% of surface area, at 3 lux)

Looking at the different rings in the flat circle from the visibility model, in a) there is a non-linear difference in contribution of each ring to total visibility. Looking at b), c) and d), the different dark areas describe decreasing surface areas of the circle to the exclusion of the lower angled surfaces. Full Object Visibility relates to the visibility of the three outer rings in comparison to overall visibility in d). This can vary significantly depending on the color.

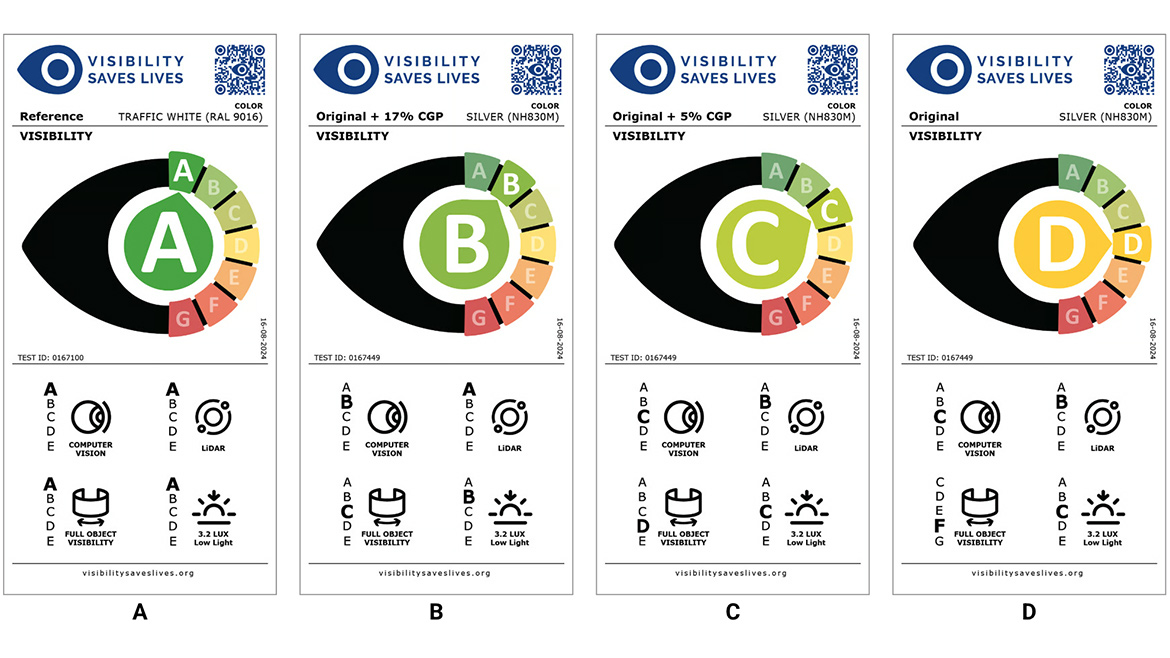

Each value is compared to a standard reference, automotive glossy solid white (“Traffic White” RAL9016), which exhibits the highest overall visibility. Label levels are based on a seven-point scale (A to G), derived from an exponential distribution, with “A” as the most visible.

The visibility labels for reference color Traffic White (RAL9016) show straight A’s for all five visibility parameters in a), and for a silver metallic (NH830M) with no CGPs in b), with 5% CGPs in c), and with 17% CGPs added to the final color formulation in d).

Enhancing Visibility: Pigment Innovations

While titanium dioxide-based whites maintain high visibility, it has been difficult to achieve safety goals with colors that allow for design flexibility. The most promising solution involves crystal glass pigments, which enhance visibility, especially at high incident angles on curved non-perpendicular surfaces. In comparative studies:

- Adding 5% CGP to a silvery metallic color significantly increased human visibility by 200% and full object visibility by 600%.

- LiDAR visibility increased by 183% with 17% CGP compared to the original color.

These improvements are made while keeping the desired look under ambient lighting, balancing aesthetics and functional safety.

Implications for Safety and Industry Practice

Implementation of the visibility label offers several benefits:

- Ability for designers to compare and tune color stylings not just for looks but for real-world visibility, using quantifiable metrics.

- Standardized and reproducible measurement of three-dimensional coating visibility, informing regulatory frameworks for new autonomous, semi-autonomous and human-driven vehicles.

- Empirical evidence for adjusting insurance premiums based on color and educating consumers about safety-related color choices.

Crystal glass pigments, combined with the 3D PoV color visibility model, can revolutionize the way vehicle colors are judged for road safety, facilitating a controlled progression toward a fully integrated autonomous future.

Conclusion

An evidence-based, standardized approach to measuring and improving 3D color visibility in mobility coatings is critical for the next phase of autonomous transportation safety. The 3D PoV visibility model and label empower both industry and regulators to quantify, compare and optimize color visibility without sacrificing design freedom. Crystal glass pigments, as a novel class of effect pigment, enable significant improvements in detectability for all key visibility modalities, such as LiDAR and Camera Visibility. Together, these advances set the stage for an integrated, safer future where color visibility saves lives.

References

¹ NRSPP – National Road Safety Partnership Program. The Effect of Car Color on Crash Risk. https://www.nrspp.org.au/resources/nrspp-quick-fact-effect-car-colour-crash-risk/. Accessed September 10, 2025.

² Mijnen, P. W.; Moerenburg, J. H. Crystal Glass Pigments: Safety Made Beautiful. Paint and Coatings Industry, February 2024.

³ Mijnen, P. W.; Moerenburg, J. H. A 3D Visibility Label for Mobility Coatings: Enhancing Traffic Safety Through Color and Sensor Perception. SAE Int. J. CAV 2026, 9 (2). doi:10.4271/12-09-02-009.

Learn more about innovations in pigments for automotive and mobility coatings, as well as other types of coatings.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!