Boosting Sustainability in Coatings with Bio-Based and Biodegradable Additives

Bio-based raw materials have been found to be appropriate substitutes for their fossil counterparts as they frequently carry a significantly lower carbon footprint and often also exhibit a better toxicological profile as well as the capability of biodegradation. In accordance with this, various parts of a coating formulation are already being substituted by more sustainable alternatives in a stepwise approach.

In this study, the performance of CITROFOL® citrate esters as coalescing agents was investigated in an architectural paint formulation and the results were compared to market standards. Furthermore, the useability of xanthan gum as a rheology modifier was studied and the performance was compared to a cellulosic thickener for the same application.

Results and Discussion

Most of the classical coalescent agents are generally considered as VOCs. Due to their high volatility over time, they contribute to emissions in the surrounding environment and require specific safety precautions.

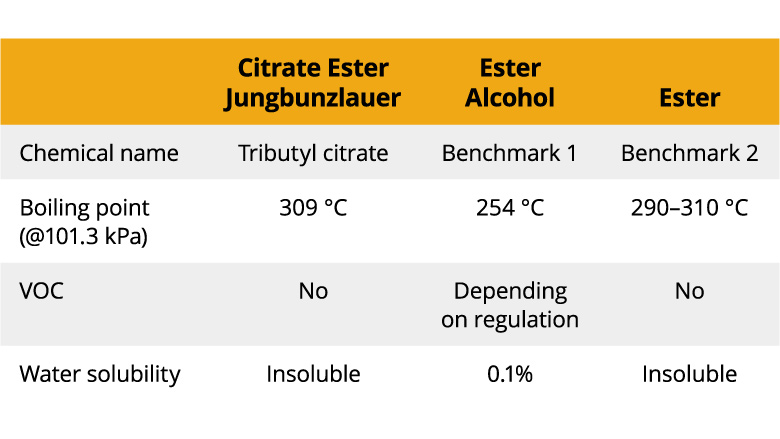

On the other hand, the citrate esters are non-VOC and comply with the latest toxicological and environmental safety requirements: they exhibit an excellent toxicological and eco-toxicological profile, provide good versatility and compatibility with numerous polymers and are characterized by highly efficient solvation, low migration and non-VOC attributes. Additionally, the citrate esters are up to 100% bio-based, depending on type. Table 1 compares significant characteristics of the three coalescent agents tested in this study. The difference in boiling points leads to a different classification in terms of VOC.

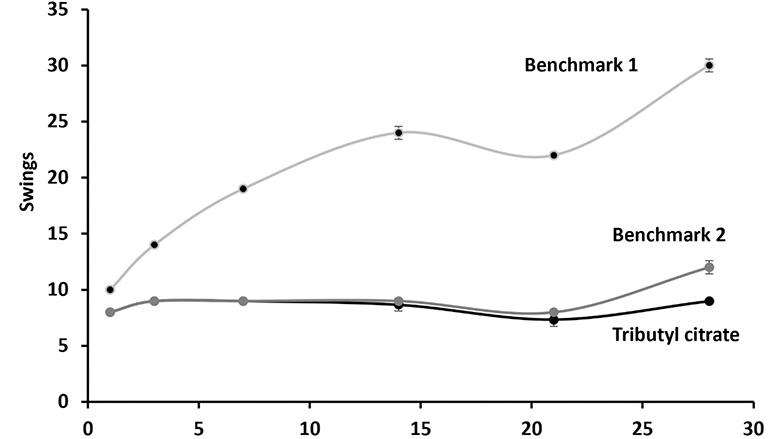

The difference in volatility and thus in VOC classification can be recognized best if a measurement of pendulum hardness over time is performed. Figure 1 shows an amount of 2.4 wt% coalescent agent incorporated in an architectural paint, which uses Acronal® S 790 as binder. In case of VOC coalescents, the solvent evaporated almost completely in less than 30 days at ambient temperature, resulting in slightly higher pendulum hardness of the coating.

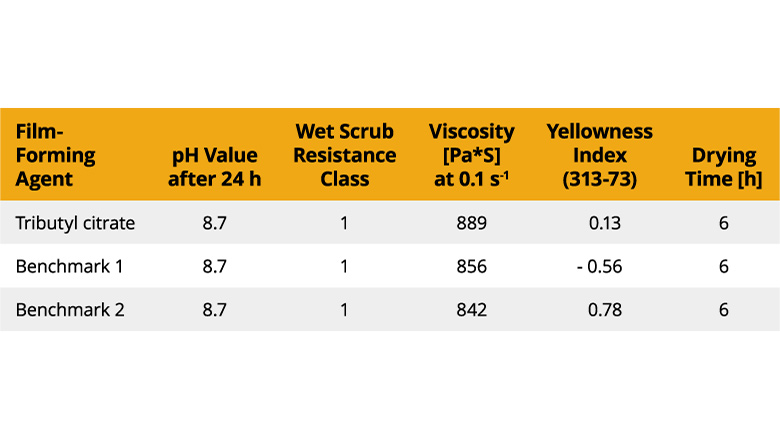

Besides having no emissions, customers expect bio-based coalescent agents to come along with no compromise in performance. For this purpose, further tests were done and the results are shown in Table 2.

The deviations between the properties of the dried paint formulations were not significant for the tested coalescent agents. The values obtained for pendulum hardness and gloss were very low. This corresponds to the typical properties of an interior flat paint formulation. Neither pH value nor wet scrub resistance were influenced by the choice of coalescent agent. The low shear viscosity values showed a small deviation between the respective batches, but are still very comparable. Concerning potential yellowing, tributyl citrate shows slightly lower value than benchmark 2. The drying time was measured by tracking the weight loss. The results show that permanent coalescent agents like citrate esters don’t lead to a prolonged drying time. The overall results confirm that citrate esters can be regarded as a valuable and sustainable addition to a paint formulation.

Xanthan gum (XG) is a natural high molecular weight polysaccharide. It is produced by fermentation of carbohydrates from renewable sources.

The addition of even small quantities of xanthan gum to water changes the rheological properties from Newtonian to pseudoplastic, thus exhibiting high viscosity at rest but thinning under shear stress. This phenomenon remains uniquely stable over a wide pH and temperature range and makes xanthan gum an attractive thickener for paint applications, where its high viscosity in the low shear range can produce excellent results in the stabilization of formulations and sag resistance.

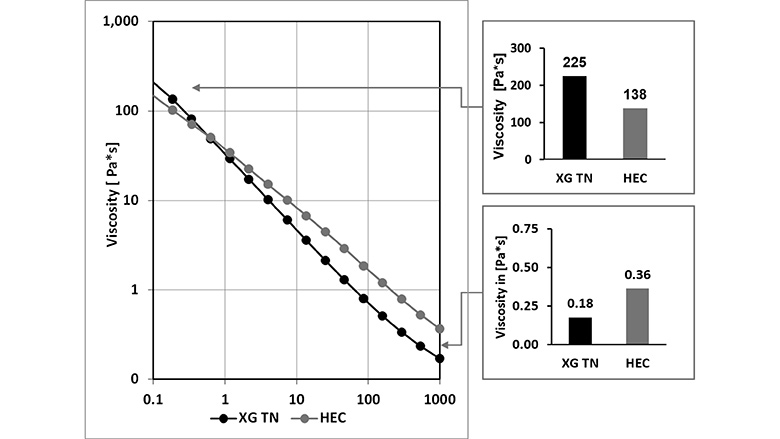

The study revealed that at similar dosage, XG leads to a low shear viscosity about 60% higher compared to a cellulosic thickener (HEC, hydroxyethyl cellulose). This effectively improves storage stability via better stabilization of pigment particles, while leading to comparable leveling and sagging. High shear viscosity on the other hand is about 50% lower, which improves applicability.

The versatility of xanthan gum is not limited to pigmented systems. It is possible to adjust the viscosity of clear coats while maintaining transparency. Due to the high content of dispersion, a premix of xanthan gum with water helps smooth incorporation.

Furthermore, xanthan gum exhibits good compatibility with other thickeners and ingredients, allowing its use in a variety of formulas, from flat paints to semi-gloss, depending on the requirements of the application.

Learn more about additives.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!