Biobased 1,5 Pentanediol as a Low-Emission and High-Performing Monomer

for Paint and Coatings

Paint and coatings producers are under increasing pressure from across the value chain to adopt more biobased, renewable raw materials into formulations. Consumer behaviors and corporate sustainability goals demonstrate continued demand for sustainable products and diversifying from petroleum feedstocks aligns with the increased importance of supply chain resilience in response to global disruptions and evolving trade policies. In this environment it is critical that paint and coatings companies can access transparent information on their raw materials to verify their bio-content, their impacts on the environment and their performance in paint and coatings formulations.

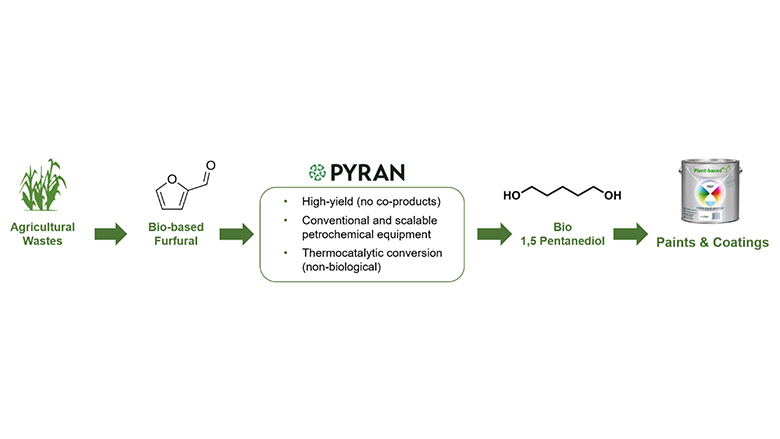

1,5 Pentanediol (1,5 PDO) is a versatile building block molecule that can be used to produce a range of longer chain molecules such as polyols that form the backbone of many paint and coatings formulations. This article investigates Pyran’s biobased monomer 1,5 Pentanediol (bio-PDO) to assess its biobased credentials, climate impact, process and cost advantages and properties in key coatings applications. Pyran developed a process to leverage the existing commercial supply of furfural, a platform chemical produced from non-food agricultural wastes, with Pyran’s proprietary chemical conversion technology to upgrade the furfural to bio-PDO (Figure 1). The process is thermocatalytic (avoiding biological fermentation) and achieves high yields and low production costs using traditional operations for the petrochemicals industry.

1,5 Pentanediol Bio-content

Demand for biobased products as a sustainable alternative to finite and volatile crude oil feedstocks continues to increase. To market biobased products to consumers, it is important for paint and coatings manufacturers to be able to validate the bio-content of their raw materials. The USDA BioPreferred® Program was created in 2002 with the goal of increasing the adoption of biobased products and reducing the nation’s reliance on petroleum.1 The BioPreferred Program helps avoid “greenwashing” by verifying manufacturers’ reported biobased content through accredited testing under ASTM D6866, which measures the percentage of biobased carbon in each material through Carbon-14 (C14) analysis.

C14 is a naturally occurring radioisotope of carbon produced in the atmosphere and present in living organisms as they intake carbon dioxide (CO₂). Once a living organism dies, it stops taking in new C14 and its remaining C14 radioactively decays over time at a rate where it is no longer detectable after approximately 50,000 years. Fossil materials such as petroleum, which are more than 50,000 years old, will not have any detectable C14 left. By quantifying the Percent Modern Carbon (pMC), or amount of C14 in a material vs. the atmosphere, it is possible to determine the amount of biobased carbon in the material.

Carbon-14 test results for Pyran’s bio-PDO versus a commercially available petroleum-based 1,5 PDO are provided in Table 1. Based on the Carbon-14 test results, Pyran’s 1,5 PDO was qualified as a USDA Certified Biobased Product.2

Life Cycle Analysis (LCA)

Biobased materials are not always lower impact on the environment when accounting for emissions and other factors from the production process. A Life Cycle Analysis (LCA) was performed to understand the associated lifecycle environmental impacts of Pyran’s bio-PDO. An LCA inventories the inputs and outputs of a production process and their associated impacts on the environment. Pyran’s LCA was performed by an established third-party LCA provider and covers the entire process “cradle-to-gate” including extraction and processing of raw materials, production of the finished product and transportation and waste stages up to the factory gate. The LCA complied with ISO Standards 14040, 14044 and 14067 and was peer-reviewed by a panel of three experts in the field.3-5

The LCA for bio-PDO was compared to an analysis of a similar petroleum-based diol, 1,6 Hexanediol (1,6 HDO). 1,6 HDO is produced from oil feedstocks alongside 1,5 PDO. Bio-PDO is expected to replace both petroleum 1,5 PDO and 1,6 HDO commercially. 1,6 HDO is used in larger volumes and has more data available which is why it was chosen for Pyran’s comparative analysis.

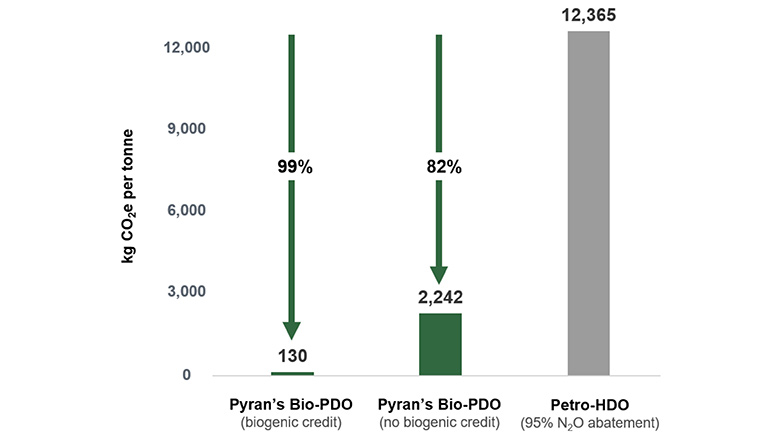

A large environmental impact from petroleum-based diols is nitrous oxide, a potent pollutant and greenhouse gas emitted during the production process. Abatement technologies to remove nitrous oxide at the source of production are implemented with varying effectiveness in existing plants across the world. Pyran’s 1,6 HDO model assumes 95% nitrous oxide abatement based on the global average in the Ecoinvent v3.11 database.

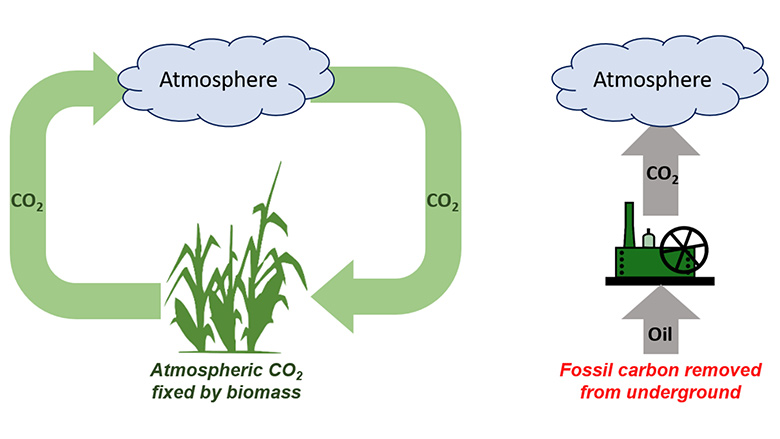

Petroleum-based products are made from fossil carbon previously stored underground which is then emitted to the atmosphere upon burning or decomposition of materials (Figure 2). Biobased products are comprised of carbon that is part of the biogenic carbon cycle, in which carbon is captured from the atmosphere by plants via photosynthesis, transferred through the food chain and released back to the atmosphere through decomposition or respiration of living organisms.

Furthermore, for durable end products such as paint and coatings, the carbon is effectively sequestered from the atmosphere into the end product for long periods of time, leading to outsized environmental and climate benefits. An LCA for biobased products like bio-PDO reports greenhouse gas emissions with and without crediting the stored biogenic carbon.

The completed LCA shows that Pyran’s bio-PDO produces 82% lower greenhouse gas emissions compared to petroleum-based 1,6-hexanediol (1,6 HDO) before accounting for biogenic carbon stored in the final products (Figure 3). This improvement is driven by Pyran’s production efficiency and the absence of nitrous oxide emissions from our process. When accounting for biogenic carbon stored in durable paint and coatings, bio-PDO has 99% lower GHG emissions than the petroleum-based 1,6-hexanediol (Petro-HDO).

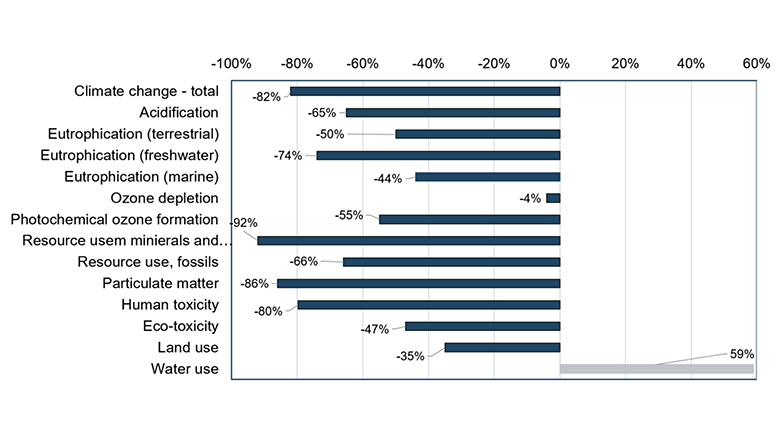

In addition to greenhouse gas emissions, bio-PDO was found to reduce impacts across every climate category assessed in the LCA except for water use (driven by biomass cultivation) as demonstrated in Figure 4.

Bio-PDO Production Advantages

Pyran’s process improves upon existing biobased routes to 1,5 PDO to overcome key economic challenges. The Pyran process uses a different synthesis route through a reactive intermediate at 80× greater reaction rates versus the traditional biobased pathway, leading to approximately 40% lower costs driven by reduced utilities, reactor capital and catalyst requirements.6 Pyran’s process produces 1,5 PDO at high yields without co-products and does not require solvents or recycling common in industrial chemical processes. The biobased feedstock furfural has been commercially produced since 1942 and does not rely on novel technology to scale.

Biobased products are often seen as more expensive than their petrochemical counterparts, with manufacturers expecting to pay a “green premium” if they want to increase the bio-content of their formulations. Pyran uses traditional scalable petrochemical equipment and industry-standard catalysts to manufacture bio-PDO cost-effectively compared to petrochemicals currently used. Petroleum-based production of 1,5 PDO requires high pressures and produces byproducts that are expensive to separate from the desired product.

Pyran has completed a front-end engineering design (FEED) of a commercial bio-PDO plant and developed a technoeconomic analysis for the commercial process based on lab and demonstration scale operating data to estimate the process economics. This analysis projects that Pyran’s process can produce bio-PDO at lower costs than petroleum-based 1,5 PDO due to the advantages noted above.

Properties of Bio-PDO Based Polyols

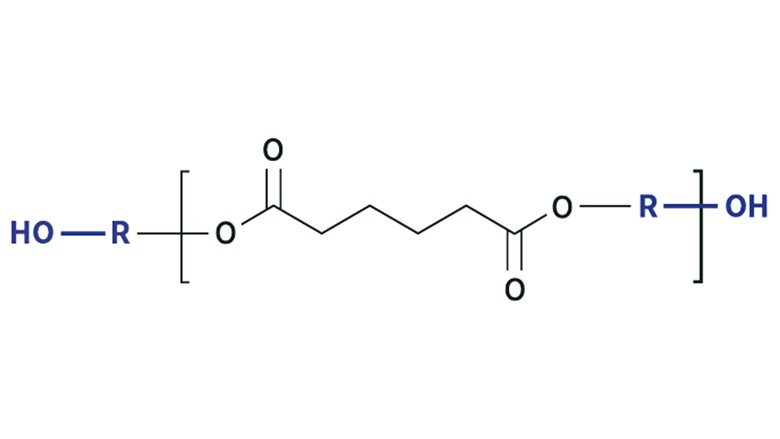

Diols such as 1,5 PDO are used in a variety of coatings, adhesives, sealants and elastomers (CASE) applications including polyester polyols. Polyester polyols are synthesized using a diol and diacid, with adipic acid-based polyols (adipates) being a prominent example (Figure 5).

Polyester polyols are commonly used in downstream polyurethane applications such as coil coatings, architectural coatings and elastomers.

Due to the high cost and limited supply of petroleum-based 1,5 PDO, polyol producers have generally worked with diols that contain an even number of carbon atoms. Interestingly, molecules consisting of even and odd numbers of carbons behave differently in polyols than what would be expected by varying chain length alone. The inclusion of an odd-numbered carbon diol disrupts intermolecular dipole forces that impact crystallinity and related properties while providing comparable viscosity and glass transition temperatures to other diols. This results in odd-numbered carbon diols having lower melting points than their even-numbered counterparts, allowing for lower processing temperatures. Pyran tested diols of varying carbon chain length (C2–C6), in comparison to bio-PDO in adipate polyester polyols to compare properties relevant to end applications (Table 2).

Pyran’s biobased 1,5 PDO has nearly identical physical properties compared to the petroleum-based 1,5 PDO, meaning current 1,5 PDO users could readily utilize biobased PDO while still achieving the desired properties. Additional adoption of bio-PDO into formulations employing 1,4 Butanediol or 1,6 Hexanediol is driven by applications where 1,5 PDO has desirable properties such as viscosity or glass transition temperature but has not previously been used due to cost limitations.

Conclusion

It is important to be able to transparently and reproducibly assess biobased materials to understand their environmental impact, cost and performance. Using standard methodologies available, Pyran demonstrates that its renewable monomer 1,5 Pentanediol (bio-PDO) is 100% biobased and achieves up to 99% lower greenhouse gas emissions vs. petroleum-based diols all while using an advantaged production process. Bio-PDO also demonstrates desirable properties in adipate polyester polyols, a key prepolymer for paint and coatings.

References

1 United States Department of Agriculture. BioPreferred | About; July 21, 2025; https://www.biopreferred.gov/BioPreferred/faces/pages/AboutBioPreferred.xhtml

2 SGS Beta. Understanding Carbon-14 Analysis; July 21, 2025; https://www.betalabservices.com/biobased/carbon14-dating.html

3 International Organization for Standardization. ISO 14040:2006(en) Environmental Management – Life Cycle Assessment – Principles and Framework; https://www.iso.org/obp/ui/#iso:std:iso:14040:ed-2:v1:en

4 International Organization for Standardization. ISO 14044:2006(en) Environmental Management – Life Cycle Assessment – Requirements and Guidelines; https://www.iso.org/obp/ui/#iso:std:iso:14044:ed-1:v1:en

5 International Organization for Standardization. ISO 14067:2018(en) Greenhouse Gases – Carbon Footprint of Products – Requirements and Guidelines for Quantification; https://www.iso.org/obp/ui/en/#iso:std:iso:14067:ed-1:v1:en

6 Brentzel et al. Chemicals from Biomass: Combining Ring-Opening Tautomerization and Hydrogenation Reactions to Produce 1,5 Pentanediol from Furfural; 2017.

Learn more about the role of sustainable raw materials in the paint and coatings industry.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!