Curing Smarter and Cooler with Low-Bake Powders

Low-Cure Powder Coatings are Delivering Faster Throughput in a More Sustainable Package

Inside this Article

- Low-cure powder coatings enable curing at significantly lower temperatures than conventional powder systems, reducing energy consumption and cycle times.

- These technologies help finishers maintain durability, corrosion resistance and color retention while improving throughput on mixed-gauge production lines.

- Lower bake temperatures expand powder coating use to heat-sensitive substrates such as plastics, wood and wood composites.

- Low-cure powders support sustainability goals by eliminating VOC emissions and reducing reliance on solvent-based liquid coatings.

- Wider cure windows improve process stability, allowing consistent oven settings across varying part thicknesses.

- Ongoing innovation is focused on faster cure times, broader performance windows and higher-aesthetic finishes for demanding applications.

From the finish on cell phones to shipping containers and monumental architectural structures, high-performance powder coatings are used in nearly every industry to make products look better and last longer. However, how those powders cure, the temperatures required for the ovens, and the performance of the finish are all evolving.

New developments in powder coatings that cure at lower temperatures are allowing OEMs and finishers to speed up production, increase throughput and reduce energy usage, while delivering the durability and longevity expected of today’s powder coating solutions.

The data tells the story.

A 2025 Precedence Research report forecasts that the low-temperature powder coatings market will grow from approximately $125 million today to more than $200 million by 2034, signaling accelerating demand for energy-efficient technologies.

Credit: PPG

Credit: PPGThis momentum is driving OEMs and finishers to adopt low-cure technologies that not only meet performance expectations but also open the door to more efficient and sustainable production.

What Are Low-Cure Powders?

Low-cure powders are designed to perform comparably to traditional powder coatings in terms of durability, chemical and corrosion resistance and color retention, but with a distinct advantage in energy efficiency over standard formulations.

In general, most industrial powder coatings require thermal heat to initiate the cross-linking chemical reaction that gives them their tough, durable finish. For conventional powder coatings, this typically occurs under temperatures of 325°F to 400°F (163°C to 204°C). However, advanced low-bake powder formulations can cure at temperatures as low as 250°F (121°C). This, in itself, is an attractive attribute for coatings operations seeking to reduce energy use.

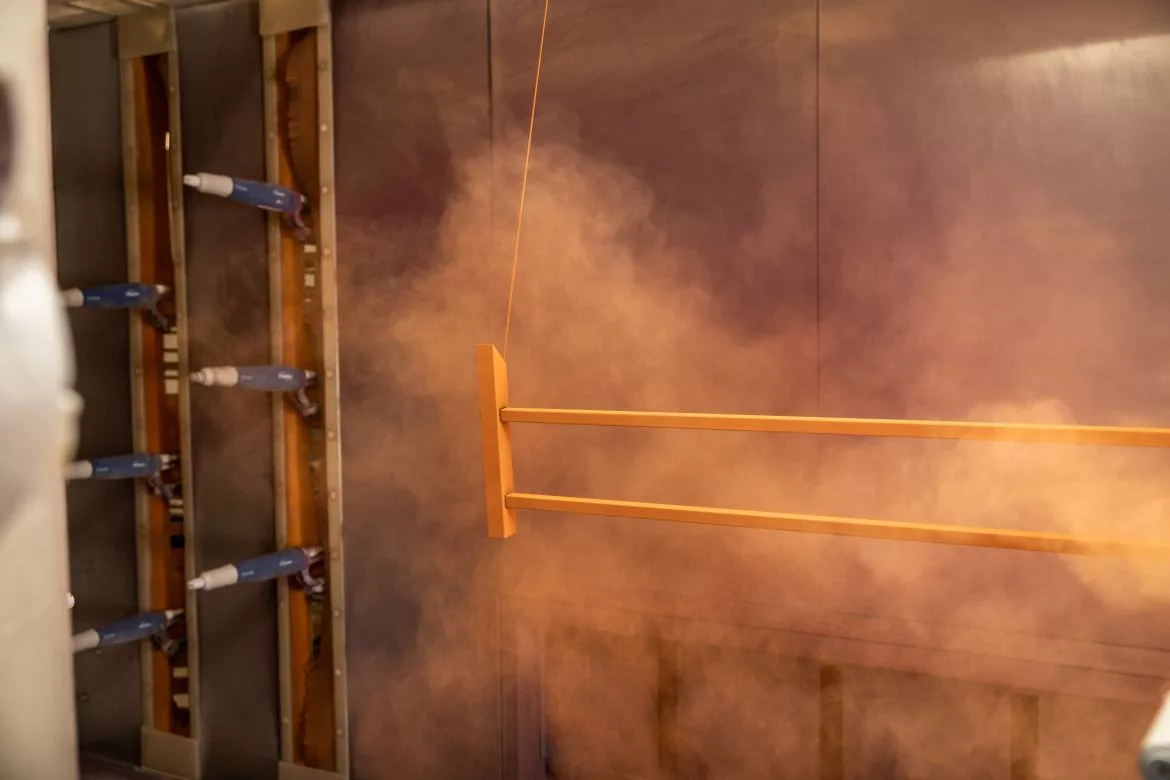

Credit: PPG

Credit: PPGWhile powder coatings have been used on metal since the 1940s, their use on higher density metal substrates is a more recent development. Products made of thicker metal naturally take longer to reach the target temperature required for a proper cure, which can create curing inconsistencies when thin and thick parts run on the same line. Low-cure powder coatings overcome this challenge by lowering the required metal temperature, making it easier to achieve uniform heating across mixed gauges.

Low-cure powder innovations are also extending the technology’s applicability for new substrate types. Reduced oven temperatures have made powder coating feasible for materials once considered unsuitable like heat-sensitive plastic, wood and wood composites. In essence, low-cure solutions are bringing the performance and sustainability advantages of powder coatings to more products and industries than ever before.

Rising Requirements for Sustainability

Generally, sustainability was not nearly as top of mind 25 years ago as it is now, and it was not a factor that drove interest in powder coatings initially. Instead, powder adoption first saw a boost when finishing operations were asking coatings suppliers for solutions that would deliver faster throughput and speedier cure times. They also needed to provide the long-lasting durability today’s manufacturers expect, on par with or exceeding the performance of traditional liquid coatings.

This led leading coatings manufacturers to prioritize the development of new resin and pigment technologies that cured faster. Over time – and as the technology improved – this allowed coaters to drop the temperatures of their ovens and reduce overall energy use. This approach maintained performance standards and strengthened the sustainability of their operations.

Credit: PPG

Credit: PPGFast forward to today, and the combination of sustainability and performance are standard expectations in the coatings industry, and low-cure powders are playing an increasingly important role. This shift is only accelerating with environmental regulations in the United States and Europe, which are limiting the reliance on liquid spray coatings because they contain solvents that emit volatile organic compounds (VOCs).

Regulations and Why Industrial Coaters Are Paying Attention

In the United States, industrial spray operations are subject to VOC and hazardous air pollutant (HAP) limits under the Environmental Protection Agency’s National Emission Standards and NESHAP regulations. This falls under the Clean Air Act (CAA), an overarching federal law, and consequences for non-compliance include hefty fines, legal liabilities and facility shutdowns. Even facilities that rely heavily on allowable spray-applied liquid coatings face ongoing monitoring, reporting and control requirements.

Directive 2004/42/EC, the European Union’s “Paint’s Directive,” also caps VOC content in coatings to reduce air pollution, including ground-level ozone and smog as well as restrictions on solvent use. Similarly, the Industrial Emissions Directive (2010/75/EU) sets emission limits and best-practice standards for industrial facilities, all aimed at minimizing pollution. The EU Green Deal, a strategy to make Europe the first climate-neutral continent by 2050, is driving much of this change.

Credit: PPG

Credit: PPGTogether, these regulations and others are influencing the reduction of solvent use globally, and coaters are responding by adopting new coatings solutions like powders.

In the U.S. and abroad, powder coatings allow finishing operations to circumvent these barriers by eliminating the solvents present in conventional liquid sprays. Powders generate virtually no VOC emissions during application, and modern low-cure formulations further reduce oven temperatures to save energy while expanding the types of substrates that can be coated. For industrial coaters, this means better regulatory compliance, lower energy costs and reliable throughput.

Beyond the absence of solvents, low-cure powder formulations take sustainability advantages to the next level by reducing oven temperatures to save energy while expanding the types of substrates that can be coated.

The Future of Low-Cure

While low-cure powders solve a number of issues presented by their liquid spray counterparts, there’s still more performance, efficiency and capability to unlock.

Leading coatings manufacturers continue to push the limits, identifying new methods and creating formulations designed to reduce both curing times and oven temperatures without compromising performance.

For instance, some innovators are exploring ways to shrink cure times down to less than five minutes, further boosting throughput on lines that are already optimized for speed.

Another area of advancement within the low-cure segment is the development of wider curing windows. For most industrial finishers, especially those running continuous lines with a mix of thin and thick metal gauges, this flexibility is invaluable.

A wide cure window allows operators to set one consistent oven temperature and trust that all parts will fully cure, regardless of metal thickness or mass. It not only achieves a full cure, but meets all required mechanical and performance property criteria for modern coatings. Previously, different gauges required constant adjustments or even separate cure schedules. Today’s modern low-cure powders offer wider process tolerances, reducing line disruptions and creating more stable, predictable and reliable production.

There are, however, practical considerations for coaters who may be transitioning from a standard cure schedule to a low-cure system. Low-cure powders are typically selected for energy savings or for substrates with less strict aesthetic requirements. Some products that require an extremely smooth, minimal-fade surface, or those relied on for high-visibility applications, may still require a standard powder solution. However, industry-leading coatings manufacturers are developing products that marry low-cure qualities with high aesthetics that can be used for automotive exterior parts, architectural panels and consumer electronics.

In addition, even with wider curing windows and today’s more flexible curing options, realizing the full return on investment of a low-bake line often requires a complete commitment to this type of operation. A single oven cannot efficiently run both low-cure and standard-bake powders at once. Therefore, coaters must evaluate where low cure makes the most sense and whether dedicating equipment to it is feasible.

Pushing the Boundaries

While low-cure powders hold several notable advantages over liquid coating formulations, the innovation and R&D behind these solutions hasn’t crossed the finish line. Leading coatings manufacturers are redefining what’s possible, identifying methods and creating formulations designed to reduce both curing times and oven temperatures while delivering a high-aesthetic appearance.

Innovation in low-cure powders is a big part of the equation. When paired with a total-solutions approach from a reliable partner, coaters can streamline operations, save time and money, and exceed customer expectations for efficiency, sustainability and durability.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!