Acrylated Performance Products for Sandable Sealers

Although unsaturated polyester systems show poor mechanical properties and low humidity resistance,4 they impart good substrate wetting and adhesion properties5,6 and they represent an economic alternative to coatings based on acrylate oligomers. It is estimated that 50% of the vehicles used in wood fillers in North America are based on unsaturated polyester resins.7

Surface Specialties has developed two acrylated experimental products, RX 02677 and RX 02678, to formulate highly filled wood sealers. These products are characterized by excellent substrate and pigment wetting and were designed to impart good mechanical properties. We have prepared model formulations of wood sealers and compared their performance properties with those obtained with sealers based on unsaturated polyester resins.

Based on our results, we conclude that the acrylated experimental products are suitable to formulate sealers with improved reactivity, properties and economics than sealers based on unsaturated polyester resins/acrylate monomer. The economic advantage results from the superior pigment wetting capabilities of the acrylated oligomers that allow the use of higher filler-to-resin ratio than with the unsaturated polyester/acrylate monomer systems.

Experimental Section

Materials and Formulations

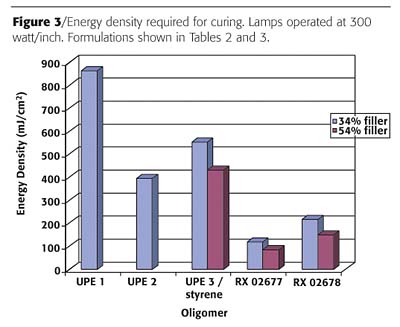

Three commercial products based on unsaturated polyester resin were obtained to compare their performance with the acrylated experimental products developed by Surface Specialties. Typical properties are summarized in Table 1.RX 02678 is a higher viscosity oligomer designed to impart better flexibility and impact resistance than RX 02677.

Tables 2 and 3 show the model formulations used for testing. The monomer and oligomer contents were adjusted to give the same resin level at a given filler concentration.

Dipropylene glycol diacrylate (DPGDA) and Ebecryl 7100, an acrylated amine, are produced by Surface Specialties UCB. Calcium carbonate was purchased from Omya Corp., talc from Luzenac America, and Irgacure 500 from Ciba Specialty Chemicals.

Methods

Formulations were prepared by blending the required amounts of reagents and adjusting the diluent to obtain the same resin content. The filler was incorporated at medium speed using a disperser. Viscosity of the formulations at 25 oC was measured with a Brookfield DV-II+ viscometer at 10 and 100 rpm, the spindle being selected according to the viscosity range.Coatings were applied on opacity charts and steel panels with a #12 drawdown bar and cured with a Fusion EPIQ 6000 curing unit using H lamps operated at 300 watt/inch. Cure response was determined by the thumb twist method, the dose being measured with an IL 390B light bug.

Mandrel flexibility, pencil hardness and reverse impact resistance were measured after exposing the samples to three times the energy required for curing.

Results and Discussion

Performance Properties

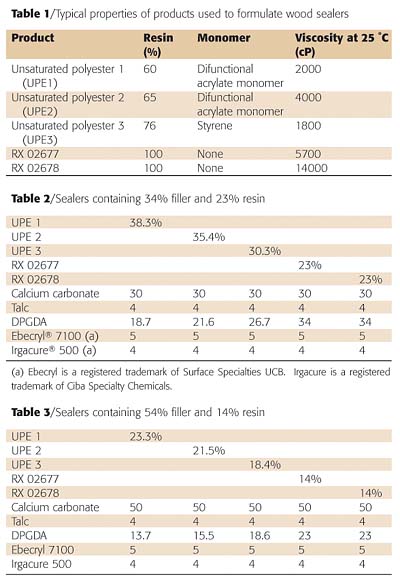

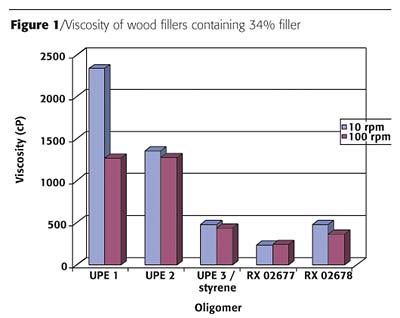

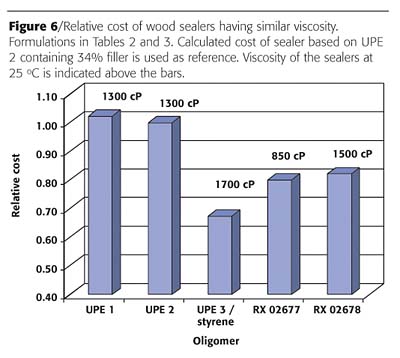

Figures 1 and 2 show the viscosity of the wood sealers based on the different oligomers. Except for the sealers based on UPE 1, pseudoplasticity of the coatings was low or undetectable.At both filler concentrations the viscosity of the formulas based on the acrylated experimental products is lower than those based on unsaturated polyesters, a consequence of the higher pigment wetting ability of the acrylated oligomers. In particular, the viscosity of the sealers based on UPE/monomer containing 34% filler is similar to the sealers based on the acrylated experimental products containing 54% filler. As a consequence, the sealers based on the acrylated experimental products turn out to be more economical than those based on UPE/monomer even though the resins are more expensive.

The viscosity of the sealers based on UPE 3 is higher than for the formulas based on RX 02677, but the difference is less significant. As a first approximation, this viscosity difference will be neglected in the analysis.

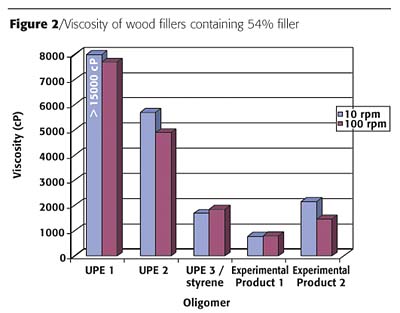

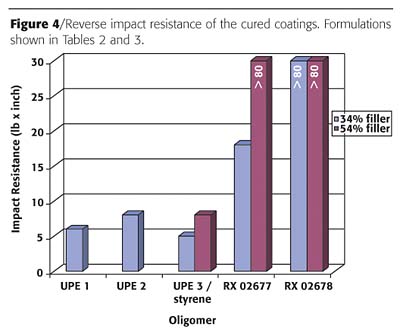

As can be seen from Figures 3 and 4, the sealers based on the acrylated performance products are three to five times more reactive than those based on unsaturated polyesters and show better impact resistance, the latter effect being more significant for RX 02677 when the filler concentration is 54%. RX 02678, being more flexible, shows impact resistance greater than 80 lb x inch at both filler concentrations.

Economic Analysis

As the results presented in the previous section show, the performance properties of the sealers based on the acrylated experimental products are superior to those obtained with unsaturated polyesters. Whether a user switches from one system to the other depends on the cost associated with this higher performance. Table 4 shows the relative cost of the different raw materials calculated from current market prices.

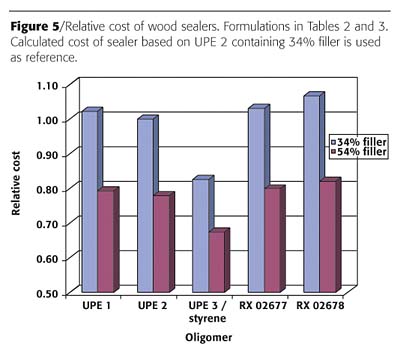

The cost of the sealers based on the acrylated experimental products are higher than for UPE/acrylate monomer systems at any given filler concentration. However, as indicated earlier, the viscosity of the sealers based on UPE/monomer containing 34% filler is similar to the viscosity of the sealers based on the acrylated experimental products containing 54% filler.

Comparing the cost of formulations having similar viscosity (acrylated experimental products containing 54% filler with UPE/monomer containing 34% filler), it can be seen there is a significant cost advantage of the wood sealer based on the acrylated experimental products (Figure 6).

Conclusions

Our results indicate that the sealers based on the acrylated experimental products show higher reactivity and better properties than those based on unsaturated polyester resins. In addition, a sealer based on the acrylated experimental products can be more economical than a sealer based on unsaturated polyester/acrylate monomer system even though the cost of the acrylated oligomer is higher. This result is a consequence of the superior pigment wetting capabilities of the acrylated experimental products, which allows incorporation of higher filler concentrations while maintaining a suitable application viscosity.References

1. Dvorchak, M. J.; Journal of Coatings Technology, March 1995.2. Balmer, B.; European Coatings Technology 2001, 10.

3. Becker Acroma "Facts on Finishing Handbook", 14.

4. Calahorra, A.; Coatings.de "Formulation Forum", March 2000.

5. Dvorchak, M. J.; Weikand, J.; Fischer, W., Conference Proceedings, RadTech North America 2002, Wood End User Session, 103.

6. Weikand, J.; Fischer, W., Paint & Coatings Industry, February 2003.

7. Skeist Incorporated, "Radiation Curing, V", 2001, 472.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!