Acrylated Products Designed for Formability and Adhesion Enhancement in Direct-to-Metal Applications

Another significant development in the can-manufacturing industry has involved the elimination of Bisphenol A (BPA) from coatings that are intended for food packaging applications. The performance benefits of polyester acrylate oligomers are highlighted, compared and contrasted to those of Bis A epoxy acrylate oligomer. Each of the formulations used in this study are in fact BPA free.

Experimental

|

| Table 1 Click to enlarge |

An application area has emerged over the last several years that entails the use of radiation-curable coatings applied to a variety of metal surfaces. The usual standards of scratch and abrasion resistance are required. But the task is made more difficult as these coatings are required to adhere when applied to a variety of metal substrates having differing surface properties that can negatively impact adhesion. In addition, if these coatings are used for cans and rigid packaging, not only is adhesion required, but a degree of flexibility is needed to withstand the rigors of the manufacturing process that result in the finished metal container. Heat and moisture resistance are also factors when considering the retort process associated with food packaging or for pipe coating that will be used outdoors.

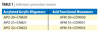

Two groups of proprietary products have been developed to meet these difficult standards. The first is a series of phosphate acid ester monomers that are best used on an additives basis. They range in functionality from mono to tri with differing levels of acid content. For discussion purposes they are described as acid functional monomers or AFMs. The second group is best described as high-molecular-weight functional acrylic oligomers that have an adhesion promoter reacted into the backbone. The oligomers are di-functional, and for best adhesion results should comprise from 30-50% of the final composition. For discussion purposes these are called adhesion-promoting oligomers or APOs. Table 1 provides a listing of these components.

Application and Cure Conditions

The conditions selected represent those that are commonly used in the metal decoration industry. Ideally the film thickness should be kept to a minimum in the interest of cost, but at the same time be thick enough that performance properties are not compromised. This is attained at the nominal film thickness indicated below. In addition, the curing conditions cited are fairly common for these applications as a thin clear is applied, negating the need for special fill bulbs. The radiometer type and results attained are also reported to avoid any variance in conditions that would affect film performance, thus ensuring consistency of the end-use test results. The application cure conditions were as follows.

- Coatings applied with a zero bar to yield a film thickness of 0.2-0.3 mils (5-7 microns).

- Cured using a 400 w/in medium-pressure mercury arc lamp at a conveyor speed of 100 fpm (350 Mj/sq.cm UVA, Power Puck radiometer trade mark).

BPA-Free Formulation Selection

|

| Table 2 Click to enlarge |

Formulation

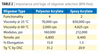

For the obvious benefits cited, a PEA was selected as the major component for this formulation (Table 3). The monomers selected for this study consisted of tripropylene glycol diacrylate (TPGDA), dipropylene glycol diacrylate DPGDA), and 3-mole ethoxylated trimethylolpropane triacrylate (3EO TMPTA). TPGDA was selected as a low-volatility and low-viscosity monomer that is commonly used for cost reasons in free radical polymerization.

|

| Table 3 Click to enlarge |

DPGDA is also an economical reactive monomer that can replace hexane diol diacrylate (HDDA). It has good viscosity-reducing properties and is more user friendly, having a Primary Irritation Index (PII) of 2 compared to 5 for HDDA. Ethoxylated TMPTA was also selected for its low skin irritancy, and it offers the added benefits of higher crosslinking and enhanced surface cure. The photoinitiator used for these formulations is a polymeric alpha hydroxyl phenyl ketone blended with 2-hydroxy-2 methyl-1-phenyl-1 propanone. The surfactant was used to ensure proper wetting of the substrate. The viscosity of the base formulation is 300 cps @ 25 °C.

Substrates and End-Use Tests

All metal test panels used were obtained from Q-Panel. Prior to coating, the panels were washed with solvent (MEK) to remove surface contamination. Substrates that are commonly used and thus selected for testing include aluminum, tin-plated steel (TPS) and cold rolled steel (CRS).

The tests conducted on cured films are as follows:

- Cross-Hatch Adhesion – ASTM D 3359- Using 610 tape;

- Reverse Impact Resistance – ASTM D 2794; and

- Solvent Resistance – ASTM D 5402.

Cross-hatch adhesion was selected as it relates the affinity of a given coating to a substrate. Reverse impact is interesting, as it relates not only adhesion but coating flexibility and provides an indication of the forming capabilities. MEK resistance gives a quick indication of how well the coating is cured.

|

| Table 4 Click to enlarge |

Acid-Functional Monomers

As a family these products can best be described as acid esters. AFM50 is a mono-functional adhesion-promoting monomer that provides exceptional adhesion to metal substrates. AFM51 and AFM53 are tri-functional versions of AFM50. They offer the same adhesion-promoting properties; however, owing to their tri-functionality, they provide faster cure response and greater hardness. Due to their high acid values these products are not recommended for use in formulations containing tertiary amines. Usage levels of 3% to 7% by weight are recommended. Acid values range from 120-195 mg KOH/g. Table 4 relates the physical properties of the monomers.

|

| Figure 1 Click to enlarge |

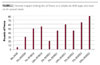

AFM Adhesion Testing

Each monomer was added to the base formulation at 3, 7 and 10% levels. Once thoroughly mixed, the coatings were applied onto each metal substrate and cured as prescribed. Upon curing, the test panels were allowed to equilibrate at room temperature for one hour before conducting cross-hatch tape adhesion testing. The “Control” formulation contained no adhesion promoter.

The trend is consistent with each AFM. As the concentration of AFM increases, the adhesion improves. The results also indicate that it is relatively easy to adhere to aluminum. Adhesion to CRS is more difficult, and adhesion to TPS is the most difficult. When adhesion performance of each AFM is examined, AMF53 yields the best overall results. The optimum level of addition is between 7% and 10%. Figure 1 details the test results.

AFM Reverse Impact Testing

|

| Figure 2 Click to enlarge |

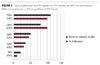

In addition to adhesion, the ability of the coating to withstand the rigors of processing is critical. Adhesion to a flat stock is relatively easy. However the metal sheets are ultimately shaped into a can body, can end or closure for a plastic or glass container. Reverse impact (RI) testing is a viable method to predict forming performance after cure. Figure 2 indicates the results.

RI was tested on TPS panel as this substrate proved to be the most difficult to adhere to. As the name implies, reverse impact testing entails dropping a weight on the reverse side of the coated test panel. As the height from which the weight is dropped increases, the impact force and the deformation of the test panel and coating also increases. The impacted area is then inspected for signs of cracking or adhesion loss of the coating. The highest force at which no coating damage is detected is reported. The data shows that as the concentration of AFM increases the force also increases. AMF53 yields the best overall performance, exhibiting the greatest RI value on the most difficult substrate.

|

| Table 5 Click to enlarge |

Adhesion-Promoting Oligomers (APOs)

APOs can be described as high-Mw acrylate-functional acrylics. Being of a high Mw, they are higher in viscosity ranging from 3,000 cps to 8,000 cps @ 60 °C. These APOs contain adhesion-promoting materials that are reacted into the backbone of the oligomer structure; thus, they are less impacted by moisture sensitivity. APOs are not to be used as additives but should comprise from 30-50% of the final formulation. As they are not acid functional, they can be used in combination with amines unlike the AFMs. Another obvious difference between the oligomers is the color. APO 20 has a Gardner color of 4 while APO 21 and 22 has APHA colors of 34 and 70 respectively. Table 5 lists the physical properties of the APOs tested.

APO Adhesion Results

|

| Figure 3 Click to enlarge |

Each of the APOs was added to the base formulation at concentrations ranging from 10 to 50%. Tin-plated steel (TPS) was selected for the test substrate as it has been shown to be the most difficult substrate for adhesion. The coatings were applied and cured under the conditions previously outlined. MEK resistance, reverse impact and cross-hatch adhesion were tested. Figure 3 shows the performance as it relates to APO concentration. The data related is typical for each APO. Adhesion and reverse impact performance improves as APO level increases. Optimum level of addition for good adhesion is 30%. Reverse impact continues to rise as more APO is added.

|

| Table 6 Click to enlarge |

Moisture Resistance Testing

Another important requirement for DTM applications is the ability of the coating to maintain its properties when exposed to water. This exposure may occur during the processing phase of packaging or in outdoor use. The coating must maintain adhesion, while exhibiting no signs of softening or surface erosion. Table 6 illustrates the formulations used for this testing.

In this case the APOs were tested in combination with a urethane acrylate oligomer. The APO used was either APO 20 or APO 22 at 20 and 30% levels of addition. The “Control” is formulation A and it contains no APO. Each coating was applied to mill-finished aluminum at a film thickness of 12 microns and cured as earlier described.

|

| Table 7 Click to enlarge |

Another measure of how well a formulation or an individual component will resist moisture degradation is to conduct accelerated weathering testing. In this case the “neat” oligomers were placed in a QUV test chamber. The cured panels were tested right after cure and at 100-hour intervals out to 500 hours QUV exposure. The yellowness index (YI) and gloss retention were recorded. The YI measures the degradation of the coating upon exposure to sunlight, while gloss retention measures the material’s resistance to micro-cracking (heat and light effects) or surface erosion related to the effects of moisture exposure. Table 7 details the cycling conditions for the QUV test chamber along with specifications for the measuring devices used and the test

|

| Figure 4 Click to enlarge |

methods employed.

QUV Test Panel Preparation

This testing differs from the previous conditions outlined, as the individual components are tested alone, not as additives to the base formulation. This will give a better indication of how the base oligomer performs. To enhance the ability to measure the YI, the oligomer containing only a photoinitiator (PI) was applied to a white base-coated panel at a film thickness of 1.5-1.75 mils. The curing conditions were also altered to better match the wavelength absorbency characteristics of the PI. Table 8 details the exact conditions.

|

| Figure 5 Click to enlarge |

QUV test results (Figure 5) show that the APOs in terms of yellowing resistance perform very well when compared to the control urethane acrylate (UA). This UA has in fact passed five years Florida exposure, inland south facing at a 5 degree angle.

Although none of the oligomers yellowed significantly, APO 20 does show a dramatic loss of gloss after 100 hours QUV exposure (Figure 6). Visual inspection showed that this is not due to micro-cracking as noted with highly functional urethanes, but is rather a loss of gloss related to surface erosion from moisture exposure.

|

| Figure 6 Click to enlarge |

Conclusions/Observations

BPA-Free

This investigation has shown that improvements can be made to the formulation by using a PEA in place of a BPA-containing epoxy acrylate. Besides the obvious advantage of being a BPA-free formulation, it provides greater formulation latitude and enhanced performance benefits by having:

|

| Table 8 Click to enlarge |

- Dramatically lower viscosity, thereby increasing the ease of handling and eliminating the need to heat the oligomer to transfer from one container to another;

- Greater formulation latitude by allowing more high-molecular-weight oligomer to be added to the formulation to improve performance without adversely impacting blending ease or increasing application viscosity;

- Faster UV cure, as the PEA is tetra-functional versus difunctional for the epoxy acrylate;

- Better yellowing resistance when compared to epoxy acrylates.

Acid-Functional Monomers, AFM

These components offer several advantages including:

- Ability to promote adhesion to a variety of metal substrates, including aluminum, cold-rolled steel and tin-plated steel;

- Not limited to metal adhesion, as these monomers have been added to formulations that are applied on other substrates, such as wood and plastic with positive adhesion results;

- Low level of addition required to impart good adhesion. Testing has shown that the optimum level is approximately 7%, resulting in minimal impact on other performance properties;

- Testing has also demonstrated that these materials not only improve adhesion to the base substrate, but in applications such as wood where multiple coats are applied, greater intra-coat adhesion was noted.

It should be noted again that AFMs should not be used with amines, as instability may result.

Adhesion-Promoting Oligomers, APOs

These oligomers work best when they are the major or one of the main components of the formulation. Testing has demonstrated that the APO should comprise between 30 to 50% of the formulation. They do however offer the following benefits:

- Improved moisture resistance as demonstrated by the water submersion test, resulting in 100% cross-hatch adhesion and in QUV exposure offering comparable yellowing resistance and gloss retention to that of an aliphatic urethane acrylate that has passed 5 years exposure in Florida;

- Improved formability as demonstrated by higher reverse impact values on TPS;

- No amine sensitivity as with the AFM.

This paper was presented at the RadTech 2010 Technology Expo and Conference, Baltimore, MD, www.radtech.org.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!