New Developments in Attritors

A useful and simple equation describing the grinding momentum is M x V (mass x velocity), which shows how the attritor fits into the family of mills. For example, ball mills use large media, normally 1/2” or larger, and run at a low (10–50) rpm. The other mills, such as sand, bead and horizontal, use smaller media from 0.3 mm to 2 mm, but run at a very high rpm (roughly 800–1,200). High-speed dispersers with no media run even faster rpm (1,200–1,800). Various types of attritors fall in between these (see Table).

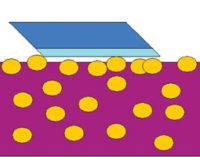

For efficient fine grinding, both impact action and shearing force must be present (see Figure 1). When wet grinding in the attritor, impact action is created by the constant impinging of the grinding media due to its irregular movement. Shearing action is present in the attritor as the balls (media) in their random movement spin in different rotation and, therefore, exert shearing forces on the adjacent slurry. As a result, both liquid shearing force and media impact force are present. Such combined shearing and impact results in size reduction and good dispersion.

The principle of attritor dry grind processing is achieved by an expanded moving bed of media. This condition is described as kinematic porosity. The dry particles are subjected to various forces such as impact, rotational, tumbling and shear; therefore, micron-range fine powders can be easily achieved. Additionally, combinations of these forces create a more spherical particle than other impact-type milling equipment.

The attritor’s versatility is gained by the ability to operate under a range of conditions: grinding media type, size and amount; different machine speeds; and variable loading or feed rate of raw material. In addition to reducing particle size, attritors also can create the highest intensity intimate blending of dissimilar materials. Specific chemicals or additives can also be introduced to the mill during the grinding process to achieve the ultimate dispersing or coating on the dry solid particles.

General Features and Options

Various types of attritors can be used in wet or dry grinding process.- A series of metal-contamination-free machines are specially designed for the ceramic industry. Several types of ceramic and polymer materials have been developed to line or sleeve the machine’s internal parts, including alumina, zirconia, silicon carbide, silicon nitride, tungsten carbide, rubber, polyurethane, and various plastics.

- Laboratory-size attritors are designed with variable speed drive for different rpm selections. Grinding tank sizes are from 100 mL to 9.5 liters.

- Production-size attritors are equipped with a 450% high torque motor for easy startup. The motor has two speeds — high speed for actual grinding, and low speed (1/3 of the high speed) for charging, discharging, and cleaning procedure. The machine’s capacity ranges from 35 to 3,800 liters.

- All grinding tanks are jacketed for cooling or heating.

- A torque meter can be installed to measure the energy input, and by using the total power consumption, one can monitor the grinding process.

- Cover seals can be provided for processing under inert atmospheres.

Three Types of Wet-Grind Attritors Batch Attritors (“S” Machines)

The operation of the batch attritor (see Figure 2) is very simple. All the material can be loaded directly into the grinding tank — no premixing or predispersing is needed. Since the top-open grinding tank is stationary, the process can be watched, and corrections and additional ingredients can be added at any time. The maximum feed material size can be up to 10 mm, provided the material is friable; otherwise, any 10 mesh or smaller material can be processed in this machine.All production “S” machines are equipped with a built-in pumping system, which maintains circulation during grinding for accelerated attrition and uniformity. The pump can also be used for discharging.

Batch attritors are used to process hard-to-grind materials, such as tungsten carbide, silicon carbide and various metals. High-viscosity slurry with up to 30,000 cps can also be processed easily in batch attritors.

Circulation Attritor (“Q” Machines)

The circulation attritor, or “Q” machine, is a combination of an attritor and a holding tank generally 10 times the size of the attritor (see Figure 3). An essential requirement of the Q-attritor system is the high circulation (or pumping) rate. The entire contents of the holding tank are passed through the attritor at least once every 7–8 minutes.

One advantage of the circulation system is that large quantities of material can be handled with a smaller investment of grinding media and attritor equipment. The system also offers better temperature control, which is achievable for two reasons. 1. The holding tank is jacketed for cooling or heating and acts as a heat sink. 2. The slurry passes through the grinding chamber very quickly (20–30 seconds per pass), therefore having less time to heat up.

These advantages are very important when the grinding chamber is lined with plastic or rubber for metal-contamination-free processing.

Continuous Attritor (“C” Or “H” Machines)

“C”-machines are best suited for the continuous production of large quantities of material (see Figure 5). “H”-machines are built the same as C-machines, but use smaller media (2-3 mm) and run 60–70% higher rpm.A well-premixed slurry is needed to be able to use this type of process. The slurry is pumped up through the bottom of the tall, narrow grinding tank and discharged out the top of the tank. The residence time required for certain fineness is controlled by the pumping rate.

The continuous attritor can be set up in a series, using larger media and grid openings for the coarser feed, then the subsequent units with smaller media to achieve the finer grind.

Attritor Grinding Media Types

Selection of grinding media depends upon several factors, some of which are interrelated.- Specific gravity. In general, high-density media gives better results. The media should be more dense than the material to be ground. Also, highly viscous materials require media with higher density to prevent floating.

- Initial feed size. Smaller media cannot easily break up large particles.

- Final particle size. Smaller media are more efficient when ultrafine particles are desired.

- Hardness. The harder the media the lesser the contamination and, consequently, the longer the wear.

- pH. Some strong acid or basic material may react with certain metallic media.

- Discoloration. Materials should maintain their original color.

- Contamination. The material resulting from the wear of the media does not affect the product or can be removed by a magnetic separator, chemically, or in a sintering process.

- Cost. Media that may be 2-3 times more expensive may wear better, sometimes 5-6 times longer; therefore, it can be well worth the extra cost in the long run.

New Developments “SDG” and “HSA” Dry Grinding Attritors

Attritor dry grinding offers the following benefits.- Process Economics. Attritors are energy efficient, compact, easy to operate and require low maintenance.

- Versatility. The attritor’s design allows modification of numerous variables to adjust changing specifications and meet the final product requirements.

- Reduced Transportation Costs. In many wet slurry processes, 50% of the gross weight is liquid.

- Energy Saving. Removal of the liquid from a wet grinding process involves not only another process step, but also requires large amounts of energy.

-

Eliminate Waste Liquid Disposal. Following stricter environmental regulations, the disposal of any waste liquid (water or solvent) is very costly.

SDG attritors use grinding balls from 5 mm to 13 mm. The shaft rpm generally runs from 75 to 500. This series of attritors is suitable for harder-to-grind materials such as metal powder, metal carbides and glass chunks. The feed material size for these machines can be quite coarse, but smaller than the grinding media chosen.

The SDG attritor is also used to make dispersion strengthened metal (DSM). In this process (known as mechanical alloying or cold welding), the kinematic porosity results in grinding media breaking the metals and additives into small particles first, then beating them together to form agglomerates. By repeating the process, the various metals are evenly mixed and dispersed to form a new composition of alloy (DSM). Pigment industries also use SDG attritors to dry grind some pigments for their color development.

High-speed attritors (HSA), a recent development, feature a patented design concept that includes a new grinding tank internal configuration and side discharge screen, which allows mills to run at higher speed, using smaller media, and continuously discharges products out of the mill by centrifugal force (see Figure 6).

HSA attritors generally operate from 400–1,800 rpm using grinding beads from 1–3 mm. This combination of high velocity and increased grinding media surface area ensure much finer grind of the processed material.

The HSA attritor is generally used in a continuous mode. Material is charged into the mill at the top by a pre-set rate feeder, and discharged out the lower side of the grinding tank. HSA-series attritors are generally used for finer feed material (–40 mesh), and produce large quantities of ultrafine powders in micron size. Applications include minerals such as calcium carbonate, talc, barium sulfate, iron oxide, and rice hull ash and flyash. The HSA is also often used for fibrous and polymer types of materials.

An air classifier or screen can be incorporated with SDG or HSA attritors to form a closed grinding process loop. By constantly taking out the fine product and reloading the oversize particles, very efficient narrow distribution fine grinding can be achieved (see Figure 7). Figure 7 / Process for Achieving Narrow Distribution Fine Grinding

Figure 7 / Process for Achieving Narrow Distribution Fine Grinding Figure 8 / DELTAMILL

Figure 8 / DELTAMILLDiscreet Pass Small Media Mill (DELTAMILL)

The DELTAMILL (see Figure 8) represents the state of the art in terms of ultrafine milling capability. This mill can use mini media as small as 0.25 mm for producing super fine dispersions. Applications include obtaining crystal clear transparent finishes and converting crude phthalocyanine blue presscake into finished blue pigment dispersions.The mill features an effectively cooled grinding chamber. This allows the mill to be highly powered and compact, resulting in less product waste and minimized media usage. The delta discs convert this high energy into superior grinding action. These features combine to produce uniform fine dispersions at high production rates.

This mill is designed for ease of maintenance, cleaning and product changeover, which translates to less downtime and greater productivity. Large removable panels provide generous space for servicing. The pressurized, two single mechanical seals are durable, reliable, and economical to repair and replace. Operating parts in the grinding chamber — including the dynamic, self-cleaning, high flow media separator — are also easily accessible. The rotating screen stays clean and is manufactured in halves for easy changeout.

The mill’s design is a result of the expertise of a team of engineers with over 100 years of combined experience in the milling industry. The mill effectively solves the most common problems typically found in many small media mills currently on the market, such as media separation, agitation, cooling, seal reliability and serviceability.

Except for a quick screen change, the DELTAMILL requires no reconfiguration to adapt to any diameter media. For those requiring it, a precision mill option is now offered that handles media as small as 0.25 mm. For metal-free grinding, a ceramic-lined grinding chamber with non-metallic agitator discs is also available.

The mill can be used in a range of fine milling applications. Products both low and high in viscosity can be milled with the same DELTAMILL by simply selecting the appropriate size media and screen slot size to suit the product to be milled. The same mill that can be run with 2 mm to 3 mm media for high-viscosity heatset or no-heat offset printing inks can be quickly and easily configured to mill low viscosity products.

Figure 9 / QC Small Media Mill

Figure 9 / QC Small Media MillQC Small Media Mill

The QC mill is based on a concept that differs from the conventional small media mill (see Figure 9). The flow direction is matched to the direction of the centrifugal force. The media is subjected to uniform dispersion and produces a strong shearing force that is assisted by the rotating force of the rotor, which in turn provides excellent grinding and dispersion. At the same time, the slurry is discharged from the separator, which is installed on the circumference of the grinding chamber.

Figures 10 and 11 illustrate the structure and principle of operation of the QC mill. The grinding chamber has a short cylindrical form, and is designed such that slurry is supplied through the shaft center, and is discharged tangentially to the cylinder.

The principle is similar to a centrifugal pump. Its interior consists of a rotor to stir the media and a separator on the circumference. Rotation of the rotor produces centrifugal force, which causes the media to form a layer sticking to the separator. At the same time, the media is attracted by the rotating rotor so that they make a rotary motion and produce a powerful shearing force.The feed material passes between the enclosed media, is ground and dispersed, and then separated from the media and discharged.

Advantages of the QC mill include the following.

1. A powerful grinding force is ensured by small media and a strong centrifugal force. The tip speed is normally between 2,000 and 3,000 fpm. Speeds of 4,000–6,000 fpm can be achieved, depending on the requirements.2. Products are consistent in quality with a sharper particle size distribution.

3. Easily disassembled and cleaned.

4. Requires less media. Since small media mills normally use high-quality media at higher costs, the lesser amount of media represents a cost savings and also means less energy consumption.

5. The large open area of the separator and the minimum amount of media used make the mill almost impossible to pack out.

6. The grinding chamber is designed with a uniform structure with no unnecessary parts. This not only increases the energy efficiency, but reduces the wear on the media and other components as well as minimizing contamination.

7. The separators consist of rings with the appropriate space between them and are thicker than the wedge wire screens. Consequently, we have seen no wear on the separators. Even so, they are easy to replace when it becomes necessary to do so.

8. Large batches can be produced with a minimum of personnel involvement. The mill can operate unattended for long periods of time.

9. Additives can be added any time during the process.

10. The grinding chamber, rotor and separator can be lined with urethane or manufactured of zirconia ceramic for metal-free contamination issues.

11. The rotors and separators are interchangeable between the metal and metal-free systems, with only the shim kit needing to be redone.

With higher and higher standards required by coating manufacturers, fine grinding/particle size reduction has become one of the most important factors for success. Over the years, attritors have proven to be an excellent and reliable means to achieve these milling tasks.

General Size Reduction Rules of Thumb

1. A specific type of machine (with fixed media, fixed operating conditions, and/or fixed equipment parameters) is most efficient in grinding a certain type of material with a certain range of feed size.2. Size reduction over a large size reduction range (such as feed size/product size >10.0) is most efficiently accomplished by using a series of grinding stages, such as grinding machines in series, the same machine used several times in sequence, or machines combined with classification steps.

3. There is no single machine type that will grind large particles to a very fine material efficiently by repeating or prolonging the process in the same machine.

4. To avoid overgrinding of material that is already smaller than desired, fine material should be removed as soon as possible by classification. This process can increase grinding throughput.

5. Uniform feed size can improve grinding efficiency a great deal.

6. Production is increased and the specific energy reduced only when a grinding circuit is operated so that the size distribution is the most steep on a Schuhman plot (e.g., the most narrow size range).

This article is based on a paper presented at the International Coatings Expo in Chicago in October 2000.

For more information on mixing equipment, contact Union Process Inc., 1925 Akron-Peninsula Road, Akron, OH 44313; phone 330/929.3333 ext. 215; fax 330/929.3034; e-mail bschilling@unionprocess.com; visit www.unionprocess.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!