Location Affects Performance of Biocide-Containing Paints

Lab tests suffer from two major weaknesses. First, they are generally limited to a few selected organisms, and second the lab does not simulate the migration and depletion pattern that occurs for biocides at the coating surface over many months of exposure. Information on efficacy against the organisms and conditions found in the natural environment is obtained by exposing the coatings under conditions in the field. Field testing using test fence exposures is a common practice in the coatings industry. It is used to assess the long-term performance of a variety of different coatings properties, such as dirt-pickup, microbial resistance, erosion, checking, cracking, chalking, flaking, blistering, fading (color and gloss), and discoloration.

Troy uses field exposures extensively to test its dry-film and wood preservative products in coatings formulations at test sites in seven distinct regions of the world. This paper covers the performance variability of tested paints for resistance to microbial growth at various sites throughout the United States. Acrylic paint containing a number of commercially available dry-film preservatives was applied over cedar test panels and exposed in three distinct locations. Three commercial, top-of-the-line paints were used as positive controls in the study. The results of three identical exposures show that the performance of the paints varied significantly by location and by the type of dry-film preservative used. This variation in relative performance by location was observed for the positive controls as well as the test paint with the various commercial dry-film preservatives. This paper includes information on some of the causative factors for the variation, and shows that reliance on data from only one exposure site can be misleading.

Study Design

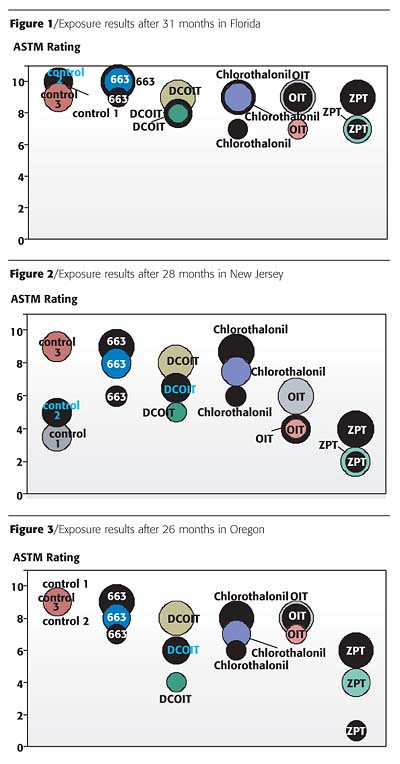

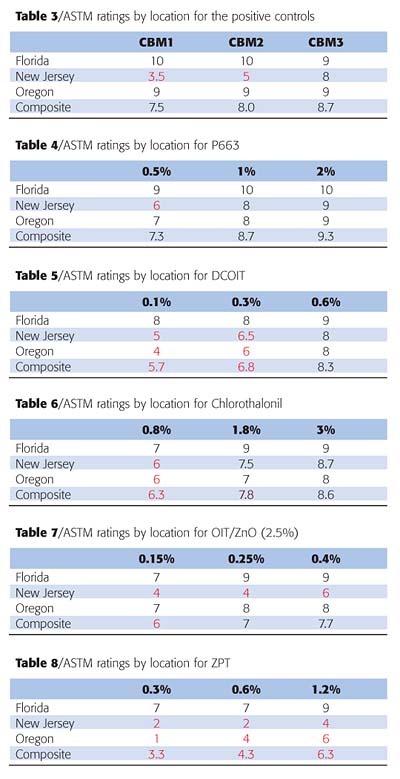

An acrylic paint (Table 2) was used to coat standard (3-foot by 6-inch) cedar test panels. The coated panels were exposed at Troy field testing locations in Florida, New Jersey and Oregon. Cedar was chosen as the wood substrate because it is the most common wood used for home exterior siding in the States. Each test panel was divided into four equal sections. The first section on the left was coated with paint with no biocide, the next section was coated with paint containing the low level of a commercial biocide, the third section was coated with paint containing the medium level of the same commercial biocide, and the last section was coated with paint containing the highest level of the same biocide. The commercial biocides that were evaluated in this study included those based on dichloro n-octyl isothiazolinone (DCOIT), chlorothalonil (CLT), n-octyl isothiazolinone (OIT), zinc pyrithione (ZPT) and Polyphase® 663, a new broad-spectrum film preservative from Troy Corporation. The use levels selected for each biocide (Table 1) were based on a combination of laboratory results and information of actual use in commercial systems. Paint formulations with OIT also contained 2.5% zinc oxide. Zinc oxide is known to enhance the performance of most biocides, and although the OIT is not being evaluated on a comparable basis with the other products, it was done so because OIT is not used without large quantities of zinc oxide in common practice. At each site, all exposures with the commercial biocides were done in triplicate with one panel placed at the top, middle and bottom of the test racks. In addition, there were two panels at each site that were entirely covered with the paint containing no dry-film preservative. These negative control panels were placed at the top and bottom of a rack.To ensure that there were no anomalies due to the paint formulation or the levels of biocides chosen, three commercial, top-of-the-line paints from three different manufacturers were used as positive controls in the study. The three commercial exterior paints were coated on the entire length of cedar panels, and duplicate panels with each commercial paint were exposed at each site at the top and bottom of the exposure racks.

All panels were rated periodically at all sites using the ASTM D 3274 rating system for microbiological growth.

Results and Discussion

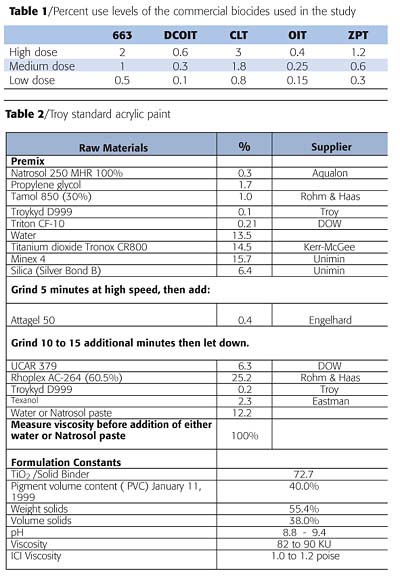

The results for each site, when there was maximum differentiation for the various treatments, are presented in bubble chart format in Figures 1, 2 and 3 for Florida, New Jersey and Oregon. The bubbles labeled as Controls 1-3 represent the performance of the three commercial paints.It is readily apparent from these figures that the commercial paints (positive controls) as well as the test paints performed differently at the three sites.

The first unexpected result was that the paints exposed in Florida lasted the longest, and even after 31 months there was very little differentiation in performance of the commercial or test paints, and none of the biocides at any level had failed (rating less than 7). However, the negative controls did fail (average 2 rating). The relative rankings of the commercial biocides were 663 > DCOIT > CLT = OIT > ZPT.

The point of maximum differentiation at the Oregon exposure site occurred after 26 months of exposure. The amount of differentiation was greater than Florida but not as great as New Jersey. By 26 months, six out of 15 of the test paints had failed, but the three commercial positive controls all performed equally well. The test products ranked in the following order, 663 > OIT > CLT > DCOIT > ZPT. The negative controls had an average rating of 2.

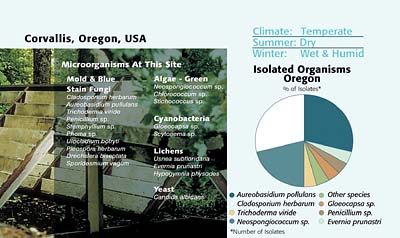

To understand the large difference in the relative performance of the commercial positive controls and the test biocides, we began to investigate what was different at the three sites. Apart from the obvious climatic differences at the three sites, we found that there was a significant difference in the types and distribution of organisms that were growing on the panels at each exposure site. Exhibits 1-3 show a summary of our findings at each site.

From these exhibits we can see that the test paints were exposed to a combination of both fungal and algal threats at all sites, but there were significant differences. In Florida, the major fungal species that were found on the panels were (in order of importance): Cladosporium cladosporioides, Nigrospora sphaerica, Aureobasidium pullulans and Alternaria alternate. In addition, there were two types of blue-green cyanobacteria (Scytonema and Chroococcus) and the green algae Chloroccum that were significant at that site.

In New Jersey, about 85% of what was found growing on the panels was the blue-stain organism Aureobasidium pullulans. The remainder consisted primarily of two other fungi (Cladosporium herbarum and Alternaria alternate). The only alga that was isolated was a small amount of Actinochloris terrestris. It is somewhat surprising that the site with the least diversity of organisms seemed to pose the biggest challenge for the various paints.

In Oregon, we found the greatest diversity of organisms growing on the panels with representation of fungi (including yeasts), algae and lichens. The fungi were represented primarily by Cladosporium herbarum and Aureobasidium pullulans. There were two other major organisms (the green algae Neospongiococum and the blue-green cyanobacteria Gloeocapsa) that represented a significant portion of the total organisms isolated.

Conclusions

These exposures demonstrate that there can be significant differences in performance of paint systems by exposure location. These differences were evident for the commercial positive controls as well as the test paint systems. This rules out the possibility that the differences observed for the test paints were merely an artifact of our standard test paint formulation, since three commercial quality formulations also demonstrated the same effects.There was a large difference in the organisms that were found at the three test site locations and this is probably responsible for the difference in absolute and relative performance for all the paints and biocides tested. Since there can be such a wide variation in product performance by location, it is very dangerous to rely on data from one exposure site to assess how a national paint product might perform. To truly assess the potential commercial performance of paint systems, they should be tested at a variety of locations across the country.

The test results for the three sites demonstrated that the best overall protection was provided by a broad-spectrum product (Polyphase 663) that could handle the wide diversity of organisms (both fungi and algae) found at the various sites. It is evident from the results that even over wooden substrates, which normally show more fungal growth than algal growth, that a film preservative active against both fungi and algae is needed to protect coatings.

It was evident that paints containing narrow-spectrum film preservatives varied the most, and the relative performance of these varied by location as the organisms at a particular site played to their relative strength or weakness.

Finally, the results point out the pitfall of using laboratory tests to assess how well a particular film preservative will perform in the field. Using our standard lab test, the paints with ZPT always performed very well relative to the other biocides, but ZPT was by far the poorest performer in the field and showed the greatest variation in performance by location in these field exposures.

For more information, call the company at 973/443.4200 or visit www.troycorp.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!