Hydroxy Ethyl Fatty Amide Effect on the Perfomance Properties of Polyesteramide Resins Based on Acrylic Copolymers

In the present study, an acid-functional acrylic copolymer has been synthesized using butyl methacrylate and maleic anhydride. In addition, the hydroxyl ethyl fatty amide of castor oil has also been synthesized and used as a curing agent for the acid-functional acrylic copolymer to form polyesteramide resins. The effect of crosslinking agent on the acrylic copolymers was examined. A series of coating compositions with varying amounts of acrylic copolymer and hydroxyl ethyl fatty amide were prepared, and their mechanical, optical and chemical resistance properties studied.

Experimental

Reagents

Castor oil was procured from a commercial manufacturer. Maleic anhydride, butyl methacrylate (BMA), diethanolamine, zinc oxide, methanol, xylene, acetone, and potassium hydroxide were of LR grade.

Synthesis of Acrylic Copolymer

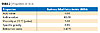

The copolymer was synthesized by dissolving maleic anhydride (1 mol) in 100 ml of xylene in a 3-neck flask with inlet for N2 gas, reflux condenser and mechanical stirrer. BMA (exactly 1 mol) containing 1.4 gm of benzoyl peroxide was added drop wise at a constant rate into the flask over the period of 2 hours keeping the temperature constant at 95 °C. The reaction mass was stirred for another 2 hours to complete the reaction. The resulting copolymer was diluted with acetone and precipitated with methanol with constant stirring. Table 1 shows the characteristics of the acrylic copolymer.

The oil (0.1 mol) was placed in a multi-necked flask equipped with stirrer, thermometer and condenser, and heated to 150 °C with the diethanolamine (0.34) and zinc oxide (0.002). The temperature was raised to 200 °C and maintained at ± 200 °C until it gave a methanol solubility test. Samples were periodically withdrawn and mixed with two volumes of methanol at room temperature; the disappearance of turbidity showed the completion of the reaction. The formation of hydroxy ethyl fatty amide was further confirmed by a TLC method.7 After reaction completion the product was dissolved in diethyl ether, washed with 15% NaCl solution and dried over anhydrous sodium sulphate. The ethereal solution was filtered and evaporated in a vacuum evaporator to obtain the light-colored hyroxy ethyl fatty amide of dehydrated castor oil. Table 2 shows the physico-chemical properties of hydroxyl ethyl fatty amide of castor oil.

Measurements

Infrared spectra of the synthesized co-polymer were recorded using a Perkin-Elmer 1750 FT-IR spectrophotometer. Molecular weight was determined by GPC (model HPLC 600, RI detector with two ultra styragel columns); polystyrene was used as a standard, and THF as eluent. For DSC analysis, a universal V4.2E TA instruments Q20 differential scanning calorimeter was used. The temperature range was kept as 20-200 °C at the rate of 20 °C/min. The analysis was carried out in an argon atmosphere at the rate of 40 ml/min. The thermal stability of the resin was measured by using a universal V4.2E TA instruments Q50 thermogravimetric analyzer under dynamic scans from 0-600 °C at the rate of 20 °C/min under nitrogen flow at the rate of 30 ml/min. Viscosity of the fatty amide was determined by Brookfield cone and plate 2000 + viscometer, at 25 °C.

Coating Sample Preparation

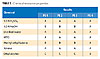

Coating compositions with varying ratios of acrylic copolymer and HEFA were prepared using xylene/acetone (95/5% v/v) as a solvent. All the compositions were thinned with the above mixture to 50% weight of nonvolatile matter. The sample designations are given in Table 3. Coating films were prepared by applying the various coating formulations on mild steel panels using a bar applicator. Film dry thickness was maintained at 40 ± 5 microns and cured for the evaluation of various mechanical and chemical resistance properties.

Results and Discussion

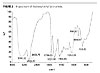

Spectral Analysis of BMA-MA CopolymerThe IR spectrum of BMA-MA copolymer, shown in Figure 1, shows the presence of an absorption band at 2972 cm-1 due to carboxylic acid of the saturated anhydride. This confirms the inclusion of maleic anhydride in the copolymer. A strong band at 1716 cm-1 may be due to the ester group of the butyl methacrylate.

Figure 2 shows the IR spectrum of HEFA. A strong absorption at 720 cm-1 and a weak band at 920 cm-1 can be attributed to (-C-H-) bending arising from poly-methylene groups (-CH2-) groups and (-CH=CH-) groups, respectively, which are present in the fatty amide. A very strong absorption band at 1050 cm-1 is thought to be arising out of (–C-O-) stretching and bending of the primary alcohol. A strong absorption band at 1460 cm-1 can be attributed to (-C-H-) bending and to the presence of tertiary amide. A strong absorption band at 3350-3400 cm-1 may be due to the free (–OH) group.

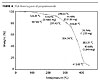

Gel permeation chromatograms are shown in Figure 3. Mn was found to be 8297 and Mw of the resin was found to be 19210.

Figure 4 shows the TGA thermogram of the polyesteramide resin. It is quite obvious that the thermal stability of the resin is quite high as only 10% weight loss is observed up to a temperature of 250 °C. Beyond this temperature a sluggish decomposition takes place and, as a result, about 50% weight loss occurs up to 370 °C and 80% weight loss occurs up to 405 °C.

Coating Film Characterization

The various coating formulation panels were cured and tested for different mechanical and chemical resistance properties, as per test methods viz. gloss at 60° (ASTM D 523-99); scratch hardness (ASTM D 5178); pencil hardness (ASTM D 3363-00); and chemical resistance (EN: 438-2:1991). The results are given in Table 4.Scratch Hardness

Scratch hardness results are shown in Table 4. The comparison of mechanical properties of the films of various compositions reveals that, in general, scratch hardness increases as the amount of curing agent (HEFA) decreases. The scratch hardness property of the film, in general, improves with an increase in the film complexity resulting from a higher degree of crosslink density. The amount of HEFA has a controlling effect in the scratch hardness of all the coating films. The scratch hardness of coating films decreases as the HEFA content increases. This might be due to the presence of a nonpolar fatty acid moiety in HEFA which brings a plasticizing effect to the films.

Cross Hatch Hardness

Cross hatch was measured by using a cross cut adhesion tester. The test was rated good if 5% of squares were removed. All the coating films showed good cross hatch hardness properties because a significant degree of crosslinking has taken place in the coating films.

Gloss

Gloss was measured using a Triglossometer (Sheen). All the coating films had good gloss.

Flexibility

Flexibility was carried out on ¼ inch Mandrel bend tester. Films of all the coatings compositions were flexible enough to pass (Table 4).

Impact Resistance

Impact resistance was measured using an impact tester. The comparison of impact resistance of the films reveals that, in general, coating films having lower HEFA content have poorer impact resistance, indicating the plasticizing effect of the crosslinking agent in the coating films. The presence of the nonpolar fatty acid moiety of the HEFA is thought to improve the film toughness resulting in the high impact resistance.

Chemical Resistance Properties

Conclusion

Acrylic copolymer was synthesized successfully using butyl methacrylate and maleic anhydride. Hydroxy ethyl fatty amide derived from castor oil was also synthesized and used as a crosslinking agent for these acrylic copolymer/resins to get polyesteramide resins. The study shows that the mechanical and chemical resistance properties of the films are dependant on the HEFA content of the compositions; an optimum acrylic copolymer and HEFA i.e., PE-4 ratio, can be selected to obtain the balanced film properties.. For further information, e-mail sukhenhbti@gmail.com or dahbti@rediffmail.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!