INNOVATION SPOTLIGHT: A Universal E-Coat

A new e-coat technology meets a wide range of specifications within a single product. Available in both black and gray, the e-coat can be used in virtually any facility and meets the volatile organic compound (VOC) and hazardous air pollutant (HAP) demands currently enforced by environmental agencies.

During the past several years, a proliferation of electrocoat (e-coat) products have been developed to meet unique specifications for various automotive parts and subassemblies, including engine cradles, service parts, springs and frames. Although some of these e-coat products have met multiple specifications, the broad performance requirements of the different parts being finished have precluded the use of a single e-coat for all applications.

Recently, BASF Corp. has developed a new e-coat technology that meets a wide range of specifications within a single product. Available in both black and gray, the e-coat can be used in virtually any facility and meets the volatile organic compound (VOC) and hazardous air pollutant (HAP) demands currently enforced by environmental agencies. The technology can provide users with greater flexibility in metal mix and part types within a single tank, and it affords the opportunity to consolidate products among multiple production facilities. These benefits, combined with outstanding performance, ultimately enable end users to implement the most cost-effective e-coating strategy in their plants.

It is clear that these requirements stretch the capabilities of e-coat products; however, the new universal e-coat can address these varied requirements. The product is designed to provide excellent corrosion protection, edge protection and other performance attributes while maintaining a smooth, Class “A” surface.

In the case of frames, specialized products have been marketed to meet demanding corrosion and edge coverage specifications. However, because these products are highly specialized, they have reduced the end user’s flexibility. This flexibility can be regained with the universal e-coat; the technology’s edge protection, corrosion resistance and smoothness enables users to process a wide variety of parts.

In addition to exhibiting these key performance improvements, the new universal product meets or exceeds all specification tests, as illustrated in Figure 1.

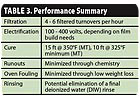

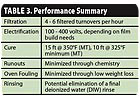

Filtration, electrification, cure requirements and other factors also must fit within current equipment capabilities. The technology’s performance characteristics are listed in Table 3 and are well within current industrial standards.

In keeping with these market developments, the new universal product is provided as a single-component feed. However, for increased flexibility, the product also can be supplied as a two-component material. This added flexibility is especially important when adjustments of the electrocoat tank P/B are needed or when new tanks are filled.

For more information about the new e-coat, visit www.basf.com.

Do you know of an innovative new product that should be featured in our Innovation Spotlight? If so, contact Technical Editor Kevin Biller at 614.286.2148 or editor@finishingtodaymag.com. Products will be covered in this department at the editors’ discretion. Click here for additional innovations.

During the past several years, a proliferation of electrocoat (e-coat) products have been developed to meet unique specifications for various automotive parts and subassemblies, including engine cradles, service parts, springs and frames. Although some of these e-coat products have met multiple specifications, the broad performance requirements of the different parts being finished have precluded the use of a single e-coat for all applications.

Recently, BASF Corp. has developed a new e-coat technology that meets a wide range of specifications within a single product. Available in both black and gray, the e-coat can be used in virtually any facility and meets the volatile organic compound (VOC) and hazardous air pollutant (HAP) demands currently enforced by environmental agencies. The technology can provide users with greater flexibility in metal mix and part types within a single tank, and it affords the opportunity to consolidate products among multiple production facilities. These benefits, combined with outstanding performance, ultimately enable end users to implement the most cost-effective e-coating strategy in their plants.

Figure 1. The new universal product meets or exceeds all specification tests.

Test Specifications

Unique tests are required for various automotive parts. A prime example is in the specifications for springs, frames and service parts. Compression or flexibility testing is crucial to ensure that the coating meets the functional needs of springs. For frames, the ability to protect edges and provide corrosion protection on a weak substrate is needed, while service parts require a smooth surface for subsequent topcoating.It is clear that these requirements stretch the capabilities of e-coat products; however, the new universal e-coat can address these varied requirements. The product is designed to provide excellent corrosion protection, edge protection and other performance attributes while maintaining a smooth, Class “A” surface.

In the case of frames, specialized products have been marketed to meet demanding corrosion and edge coverage specifications. However, because these products are highly specialized, they have reduced the end user’s flexibility. This flexibility can be regained with the universal e-coat; the technology’s edge protection, corrosion resistance and smoothness enables users to process a wide variety of parts.

In addition to exhibiting these key performance improvements, the new universal product meets or exceeds all specification tests, as illustrated in Figure 1.

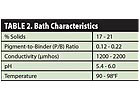

Table 1.

Tank Operation

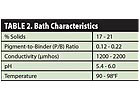

Regardless of performance attributes, any e-coat that is designed for wide use must be operationally robust. The physical characteristics of the feed materials and the bath must be operational within current facilities without the need for additional equipment. Tables 1 and 2 show the characteristics of the universal e-coat, all of which are consistent with typical market expectations.Filtration, electrification, cure requirements and other factors also must fit within current equipment capabilities. The technology’s performance characteristics are listed in Table 3 and are well within current industrial standards.

Table 2.

VOCs and HAPs

Environmental considerations are vital when choosing a coating. The universal e-coat is designed with a low VOC content and no HAPs, which is critical for compliance with the stringent permitting requirements faced by many facilities. The technology eliminates the need to track HAPs during the curing process to ensure that a facility is compliant.

Table 3

One-Component Delivery

Another consideration in running an e-coat is the method by which materials are delivered to the finishing operation. Traditionally, the emulsion and paste have been delivered as separate components. However, during the past few years, the industry has moved toward supplying these materials as a one-component mixed feed. This method of delivery provides for a simplified feed operation at the e-coat facility, as well as simplified control of the pigment-to-binder ratio (P/B) in the tank.In keeping with these market developments, the new universal product is provided as a single-component feed. However, for increased flexibility, the product also can be supplied as a two-component material. This added flexibility is especially important when adjustments of the electrocoat tank P/B are needed or when new tanks are filled.

A Universal Solution

The new e-coat meets or exceeds the requirements for a variety of parts with varied performance specifications that are used in the automotive industry. In addition to many standard performance requirements, such as salt spray, adhesion and chip resistance, the technology also meets stringent corrosion performance and edge coverage requirements without sacrificing appearance and smoothness. With all of these benefits, the universal e-coat provides a degree of flexibility that is needed in the automotive parts e-coat industry.For more information about the new e-coat, visit www.basf.com.

Do you know of an innovative new product that should be featured in our Innovation Spotlight? If so, contact Technical Editor Kevin Biller at 614.286.2148 or editor@finishingtodaymag.com. Products will be covered in this department at the editors’ discretion. Click here for additional innovations.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!