New Low-VOC Coalescents for Exterior Coatings

Dibenzoate Technology - A Viable Alternative

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

Credit: Emerald Performance Materials

References

- Butt, J.; Joshi, M.;Strepka, A. Film-Forming Aid to Minimize Volatile Organic Content in Exterior Applications, Proceedings of the 37th Waterborne, High-Solids and Powder Coatings Symposium, New Orleans, LA, 2010, 31-45.

- Arendt, W.; McBride, E. New Dibenzoate Plasticizer/Coalescent Blends for Low-VOC Coating Formulations, Proceedings of the 38th Waterborne, High-Solids and Powder Coatings Symposium, 2011, 419-429.

- Arendt, W.; McBride, E. New Dibenzoate Plasticizer/Coalescent Blend for Low-VOC Coating Formulations, Coatings Tech2011, 8, 26-33.

- Arendt, W.; Hanes, R.; McBride, E. New Plasticizer and Coalescent for Graphics Applications, Proceedings of the 39th Waterborne, High-Solids and Powder Coatings Symposium, 2012, 442-457.

- Arendt, W.; Hanes, R.; McBride, E. Advances in Low-VOC Coalescent, PCI, 2012, 28, No. 8, 40-44.

- Arendt, W.; McBride, E.; Hanes, R. Low VOC Tri-dibenzoate Blend in Exterior Coatings and Interior Paint Based on Harder Acrylic Polymers, Presentation at the Cleveland Coatings Society Sink or Swim Conference, June 4-5, 2012.

- Arendt, W.; McBride, E.; Hanes, R. Low VOC Tri-dibenzoate Blend in Exterior Coatings and Interior Paint Based on Harder Acrylic Polymers, Presentation at the Coatings Trends and Technologies Conference, September 11-12, 2012.

- RHOPLEX™ VSR-50, Product Data Sheet for Rohm and Haas, Feb 2008.

- RHOPLEX™ MULTILOBE (ML 200), Product Data Sheet for Dow.

APPENDIX 1 » Exterior paint formulation used in the evaluation.

Acrylic flat

| Ingredient Type | Chemical Name/Class | Pounds |

| Water | Dihydrogen oxide | 254 |

| Thickener | Hydroxyethylcellulose, glyoxal treated | 3 |

| Propylene glycol | 1,2-propanediol | 16 |

| Surfactant | Nonionic surfactant, HLB = 12.6/dispersant | 1 |

| Defoamer | Oil-based defoamer | 2 |

| Dispersant | Sodium salt of maleic anhydride copolymer | 14 |

| Pigment | Titanium dioxide (rutile) | 200 |

| Extender | Sodium-potassium alumina silicate | 140 |

| Extender | Diatomaceous earth alumino-silicate | 20 |

| In-can preservative | 5-chloro-2-methyl-4-isothiazolin-3-one/ microbicide | 2 |

| Biocide | 4,5-dichloro-2-N-octyl-3(2H)-isothiazolone/fungicide,algicide | 6 |

| em>Grind | ||

| Let down: | ||

| Polymer8 | Acrylic emulsion, Tg 9 ºC/emulsion | 360 |

| Polymer | Opaque polymer, particle size: 0.4 microns | 66 |

| Coalescent | Plasticizer | 8/td> |

| Surfactant | Nonionic surfactant/HLB = 12.6 | 0.5 |

| Defoamer | Oil-based defoamer | 2/td> |

| Thickener | Nonionic HEUR/thickener | 3 |

| Total | 1108 |

Acrylic semigloss

| Ingredient Type | Chemical Name/Class | Pounds |

| Water | Dihydrogen oxide | 65 |

| Dispersant | Hydrophobic copolymer/pigment dispersant | 13 |

| Surfactant | Sulfosuccinate/anionic surfactant | 2 |

| Defoamer | Polysiloxanes, 0 VOC/silicone defoamer | 0.5 |

| Pigment | Titanium dioxide (rutile) | 225 |

| Filler | Hydrous aluminum silicate, particle size=0.2 microns/extender | 10 |

| In-can preservative | 5-chloro-2-methyl-4-isothiazolin-3-one/ microbicide | 2 |

| Grind | ||

| Letdown | ||

| Polymer 7 | Acrylic emulsion, Tg 12 ºC | 484 |

| Polymer | Opaque polymer, particle size: 0.4 microns | 43 |

| Plasticizer/coalescent | Plasticizer | 4 |

| Surfactant | Nonionic surfactant, HLB = 12.6/wetting aid | 1 |

| Defoamer | Polysiloxane | 1 |

| Propylene glycol | 1,2-propanediol | 7 |

| Ammonia (28%) | 28% ammonium hydroxide aqueous | 2 |

| Thickener | Nonionic HEUR | 17 |

| Thickener | Nonionic HEUR | 4 |

| Biocide | 20% IPBC (3-iodo-2-propynyl-n-butylcarbamate)/fungicide | 8 |

| Water | Dihydrogen oxide | 154 |

| Total | 1040 |

APPENDIX 2 »Test methods employed.

| Test | Reference/Method |

| pH | ASTM E70 |

| Stormer viscosity | ASTM D562 |

| ICI viscosity | ASTM D4287 |

| Contrast ratio, reflectance, and CIE values | ASTM D2805, E97, D2244 – 3 mil wet film over a Leneta 3B chart dried for 5 days. Contrast ratio is reflectance of black over reflectance over white. |

| Gloss and sheen | ASTM D2243 |

| Low-temperature coalescence | Paint and equipment conditioned at 40 °F for 2 h. Paint drawn down on a Leneta Form 3B to 6 mils wet. The films were dried horizontal for 24 h and rated (10= Excellent, 0= Very poor). |

| Flow and leveling | ASTM D4062 |

| Dry adhesion | ASTM D3359B |

| Wet adhesion | ASTM D6900 |

| Early blister | ASTM D714 |

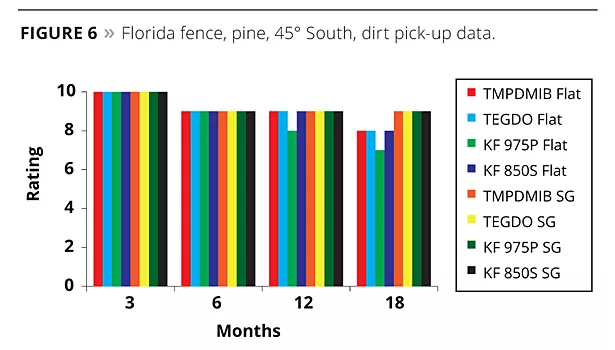

| Accelerated dirt pick up | A paint sample was applied by 3 mil drawdown on an aluminum Q36 panel. The panel was allowed to dry overnight before placing in the QUV chamber for 7 days of exposure. The top half of the panel was covered and synthetic dirt (brown iron oxide dispersion) spread evenly over the uncovered portion. The panel was placed in a 120° oven for 30 min, removed from the oven and the loose dirt was removed by tapping on the panel. The top portion of the panel was uncovered. The % Y reflectance of the tested part and the untested part were read. The % Y reflectance retained was reported. The higher the %, the better the dirt pick up resistance. |

| Blocking resistance | ASTM D4946 |

| Scrubbability | ASTM D2486 |

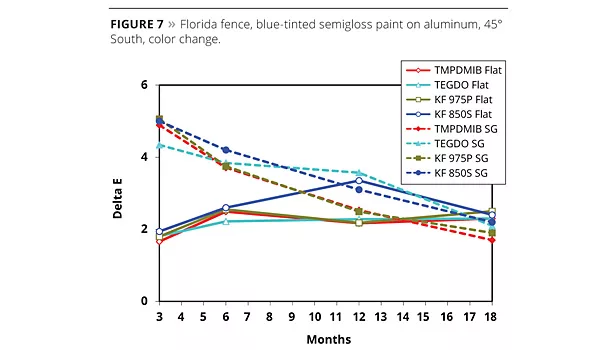

| Exterior panel preparation | Yellow Southern pine was used; application was at a natural spread rate of 400 square feet per gallon. South 45° and 90° panels self primed, two coats. North 90° the wood was primed with a waterborne acrylic primer and two coats of experimental paints. Two ounces of phthalo blue colorant were added to each paint. The 4 mils wet colored paint was applied to aluminum panels. |

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!