Shake, Rattle and Hum

Acrylic Chemistry Adds Noise-Abatement Functionality to Thick-Film Coatings

We can’t see it, but we can certainly hear it. From the rattle of a car engine to the drone of a dishwasher, vibration-induced sound is all around us. It emanates from just about anything with moving parts: HVAC systems, washing machines, buses, trains, cars and more. Sound-damping technology helps bring quiet to the chaos by reducing the mechanical vibrations that create these unwanted sounds. In automotive and other applications, a common method of sound damping involves placing thick bitumen pads between door frames, under floor boards and other vibrating parts. While these materials play a critical role in noise mitigation, they are not compatible with automated assembly. Pads must be cut, glued and installed by hand; they can be particularly difficult to place in hard-to-reach areas of an automobile or other end product.

Recognizing a need for streamlined solutions, Dow developed a portfolio of waterborne acrylic resins to facilitate the replacement of bitumen pads with thick-film coatings. Known as liquid-applied sound damping (LASD), this technology offers a number of key OEM benefits versus traditional pads, including easier application, higher damping performance, less weight and less waste. For coatings formulators, the technology offers an opportunity for new market sales: potential applications include automobile manufacturing, appliances and commercial construction.

Sound in Motion

Motor vehicle manufacturers have taken steps to reduce vibration and sound for many years. Some of the earliest automotive solutions simply stiffened the metal panels by adding beads and ribs. While this was an effective method of increasing rigidity, its limitations added complexity to the panel design and manufacturing process. Further, it added a considerable amount of weight to the automobile while not effectively dissipating sound. Today, the migration from steel-frame to unibody construction in automotive manufacturing presents additional sound-damping challenges due to the use of thin sheet metal and hollow tube forming. These features contribute to vehicle weight reduction, better gas mileage, and crumple zones for higher safety ratings and passenger protection. They also mean that vehicles can transmit more unwanted sound, thereby increasing the noise, vibration and harshness (NVH) that adversely affect ride comfort. Increases in NVH also may result when thinner sheet metal is used in appliances and other similarly constructed products.

Liquid-Applied Sound Damping

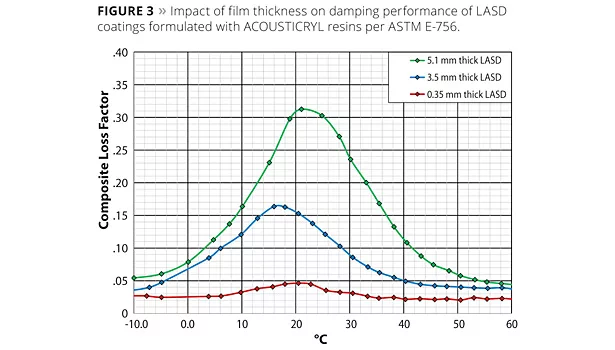

ACOUSTICRYL™ waterborne acrylic resins bring sound-damping capability to liquid-applied coatings through innovative technology that transfers mechanical stress into proprietary viscoelastic polymers. Research demonstrates that this mechanism offers improved sound-damping performance versus bitumen pads, as shown in Figure 1 by the increase in the Composite Loss Factor (CLF) over key temperatures of interest. CLF is a standard measure of sound damping performance: its value equates to the ability to remove vibrational energy from a substrate. A higher CLF value demonstrates greater removal of sound energy.

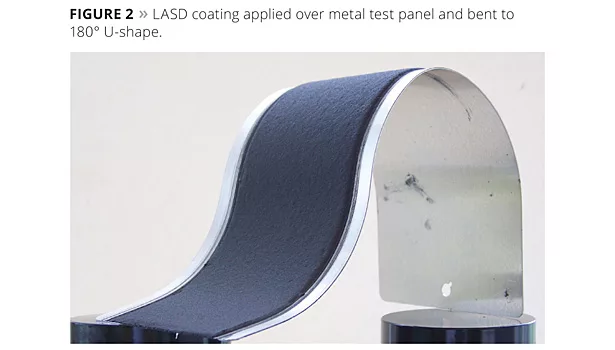

In addition to the performance improvements associated with a higher CLF, ACOUSTICRYL resin technology offers a number of key material handling and application benefits in comparison to bitumen pads. To accommodate variously configured spaces within an automobile, for example, bitumen pads must be stocked in various shapes and sizes. This complicates inventory management and increases the space needed for storage. In addition, bitumen pads are often trimmed to fit on-site, leading to material waste. ACOUSTICRYL resins, by contrast, offer a single-source solution that not only accommodates multiple auto or appliance configurations, but also provides easier access to hard-to-reach places. They are compatible with automated application, require less inventory, take up less storage space and generate less material waste. The versatile technology can be spray applied at various thicknesses to virtually any sound-transmitting substrate, including challenging curved or unique shapes, and offers a level of flexibility that can allow for post-spray steel sheet bending and forming (Figure 2), all of which enable more complete coverage and effectiveness. These features are in addition to the inherent benefits of low odor and low VOC associated with waterborne versus solventborne coatings.

How It Works

LASD coatings are typically 2 to 4 millimeters (~80 to 160 mils) thick, but can be thicker or thinner depending on factors related to the substrate and performance requirements.

As demonstrated in Figure 3, the damping performance of ACOUSTICRYL resin technology is correlated with coating thickness: thicker coatings offer higher damping performance, and vice versa. As a result, this new technology offers on-the-go customization of damping performance versus bitumen pads of pre-determined thicknesses. This means high vibrational spots may be treated with a thicker coating for higher damping performance, while moderate vibrational spots may be treated with a thinner coating for moderate damping performance. This customization feature helps to further reduce the material cost and weight associated with automotive and/or OEM noise reduction (up to 35% lower weight versus bitumen pads).

Demonstrating Sound Reduction

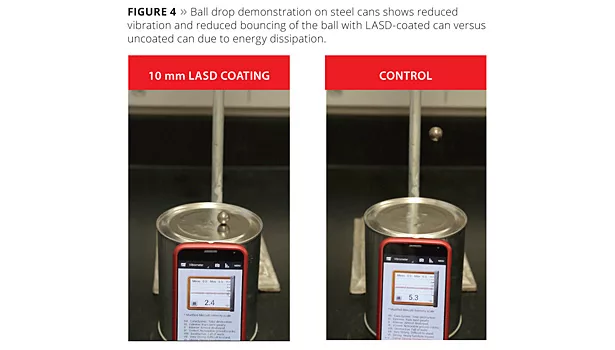

While CLF is the accepted scientific measurement of the sound-damping performance of LASD coatings, the effects of sound reduction may be observed more simply through practical lab demonstrations. For example, a ball drop demonstration was performed in the LASD research lab at Dow’s Northeast Technology Center to audibly and visually capture the ability of the coating to remove vibration. In this videotaped demo, a steel ball-bearing was dropped from equal height onto an uncoated and LASD-coated quart steel can. Audibly, the resonating sound was noticeably quieter, less harsh and dissipated more quickly when the steel ball-bearing was dropped onto the LASD-coated can. Visually, the ball dropped onto the LASD-coated can did not bounce as high and stopped bouncing almost immediately as compared to the uncoated can demo, where the steel ball-bearing bounced higher and for a longer period of time. This visual difference is reflected in the video still presented in Figure 4. (The complete video may be viewed at www.dow.com/coatings.)

Conclusion

Without the control of noise and vibration in metal surfaces, the subtle soundtrack of modern life would resemble more of a steady roar. Conventional solutions such as bitumen pads help to keep noise levels down, but are generally difficult to produce and apply, add a considerable amount of weight to the end-use product, and introduce high emissions. ACOUSTICRYL resin technology is a sprayable alternative that tackles noise management through liquid-applied sound damping. The technology represents a relatively new coatings category, offering key advantages over bitumen pads. These benefits include excellent damping performance, automated application, reduced weight, multifunctional use and simplified inventory. Because it is waterborne, this new resin technology also helps to lower VOC emissions and reduce worker exposure while maintaining high-efficiency processing through various airless spray application systems that can be guided by automated control. From home appliances, to automotive transportation to commercial architecture and more, ACOUSTICRYL technology is helping to make noise management easier and life quieter.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!