New Coating Chemistries Boost Efficiency for Automakers

Whether it’s a coupe, truck, SUV or hatchback, our vehicles all require durable coatings to withstand the rigors of daily driving while maintaining a desired aesthetic and color, both inside and on the exterior.

Although these topcoats and basecoats are invisible, they require a surprising amount of energy to apply and cure – painting and coating are the largest energy consumption units in automotive assembly plants, consuming 60 percent of total energy used.

Much of this energy is used in painting booths and the ovens used to cure paints and coatings, highlighting the importance of developing more effective automotive coatings for base and topcoats.

Advances in coating technologies, including self-crosslinking polyurethane dispersions (PUDs) and hyperbranched aliphatic polyester polyols, have been shown to perform exceptionally well in laboratory testing and deliver key benefits to coatings, including lower curing temperatures and improved flexibility and pot life.

By reducing the required curing temperature or improving scratch resistance and reflow properties, auto manufacturers and body shops can obtain process efficiency gains, cost savings, improved color harmony and uniformity, and a reduced environmental impact.

Self-Crosslinking Polyurethanes: The Next Step

Traditional solvent-based coatings, even 2K systems, require a high temperature for the crosslinking process for curing to occur and need to be mixed prior to application, limiting their effective pot life.

Self-crosslinking PUDs work differently. Instead of reacting right after mixing like in similar 2K systems, the crosslinking agent attaches to the functional polymer groups after a driver such as heat or water evaporation is introduced. This activates the crosslinker, which activates and reacts with different functional groups on the polymer to form a crosslinked film.

Self-crosslinking resins offer several advantages over 2K crosslinking systems, including excellent chemical and stain resistance, improved hardness and flexibility range, and VOC reduction capabilities. As they can self-crosslink at ambient temperatures, self-crosslinking PUDs can reduce the required curing temperature for the coatings they’re used in to as low as 80 °C (176 °F). This also extended pot life and makes them easier to store and transport.

“PUDs and polyurethanes in general can offer these unique mechanical properties across a broader temperature range,” says Tony Neely, a Technical Specialist at BASF. “They can provide flexibility without tackiness and hardness without brittleness.”

JONCRYL® U 4501 from BASF is a new self-crosslinking aliphatic polyurethane dispersion that can be used in coatings for the automotive and wood coating markets to create effective coatings without triethylamine and NMPs.

The main crosslinkers in 2K systems are isocyanates and aziridines, both sensitizers that can pose a safety hazard to handlers and applicators, in addition to the environmental concerns surrounding them.

Exposure to isocyanates has been found to be a leading cause of chemical-induced occupational asthma, and aziridines are classified as hazardous carcinogens by some governments.

Water-based PUDs avoid this issue, relying on their chemistry to improve the polymerization process to effectively link the polymer chains together without sensitizers, thereby also reducing the amount of VOCs introduced into the environment.

Testing Self-Crosslinking PUDs

To assess its performance against traditional systems and effectiveness in the final coating formulation, JONCRYL U 4501 underwent a variety of industry-standard tests measuring key functionalities, including adhesion, flexibility, abrasion and chemical resistance.

The self-crosslinking PUD from BASF went head-to-head with several similar coating additives, including a self-crosslinking PUD/acrylic hybrid, a self-crosslinking PUD designed for metal coatings, and a self-crosslinking PUD with a lower solvent composition.

Test coatings were white pigmented formulations made with the PUDs, and all formulations were drawn down on cold-rolled steel. The dry film thickness (DFT) was approximately 1.6-1.9 mils for all samples, which were cured at 25 °C and 50% humidity for 7 days.

The adhesion test was conducted under ASTM D3359 using the X-scribe method, in where the coating is scribed to the substrate with a sharp knife blade in a specific pattern. Next, a pressure-sensitive tape is applied and then rapidly pulled from the surface. The coatings are given a score from 0 to 5, where 0 represents delamination and 5 represents perfect adhesion. Four separate tests are completed, consisting of both a dry and wet adhesion test after 1 and 7 days.

The BASF self-crosslinking PUD offered the best performance overall, with a score of “4” in each test segment. All other PUDs scored “0” in the day 1 wet adhesion test, and only the competitive PUD B scored 4 or higher in the other tests.

The chemical resistance test was also conducted on cold rolled steel, under ASTM D1308-02 methods to determine any objectionable alteration in the surface, such as discoloration, change in gloss, blistering, softening, swelling, loss of adhesion, or special phenomena due to exposure.

The BASF PUD performed well, with a score of “31” following tests on nine different chemicals, and a rating of 0-5 for each, where 0 = failure and 5 = no effect. PUD B also scored 31, and the others scored 30.

Flexibility and resistance to impacts and abrasion are also important characteristics for these coatings. Tested using a ¼-inch conical mandrel bend tester under ASTM D522, all tested PUDs passed without breaking, with the exception of the PUD/acrylic hybrid, which also showed poor performance in the direct and reverse impact test.

Adhesion Advantage

The ability to effectively adhere to a wide array of substrates is an important characteristic for self-crosslinking PUDs. By readily adhering to more substrates without drastic changes in curing temperature, plastic and metal components can be cured simultaneously without damaging more temperature-sensitive substrates.

“Automakers can see large efficiency gains by being able to cure multiple substrates, along with large cost savings from being able to cure at a lower temperature,” says Neely. “They may also achieve improved appearance uniformity across various substrates, because the applicator is using the same batch of paint, providing better color harmony across the whole body of the vehicle.”

The flexibility of self-crosslinking PUDs also allows them to be easily blended with waterborne acrylic resins for additional resistance properties. BASF’s JONCRYL U 4501 is available in North America for use in automotive basecoats and interior coatings.

Topcoat Tech

In addition to basecoats and interior coatings where self-crosslinking can play a large role, other promising new technologies are changing the way formulators look at the high-gloss topcoats buyers have come to expect from their vehicles.

Linear polyester chains in topcoat formulations provide scratch resistance and flexibility to coatings, but they can also reduce hardness and chemical resistance, especially for higher-solids (lower-VOC) resins.

Hyperbranched aliphatic polyester polyols make use of hyperbranching technology to provide the scratch and abrasion resistance offered by linear chains, while delivering excellent chemical and weather resistance, hardness, and adding enhanced reflow characteristics and extended pot life.

These hyperbranched chains form a spherical structure, which, paired with its dual functionality (-OH and -COOH) groups, prevents chain entanglement that can cause increased viscosity and reduce pot life.

“Due to their shape, with hyperbranched polyesters there is no chance for the molecules or different polymers to entangle and increase the viscosity,” says Susana Porzio, a Technical Specialist at BASF. “This allows for a lower viscosity in the coating, allowing for increased solid content, which in turn will decrease the cost of the final formulation and also give off less VOCs.”

The resulting reflow capabilities from hyperbranching allows for easy repairability in the event of a scratch, as refinishers can reheat the coating and make repairs while maintaining 95% of the original gloss.

Linear vs Hyperbranched

BASONOL® HPE 1170 B, a new hyperbranched aliphatic polyester polyol from BASF, was tested against competitive linear polyesters for scratch resistance and reflow behavior, hardness development, pot life and drying time, and weathering and chemical resistance.

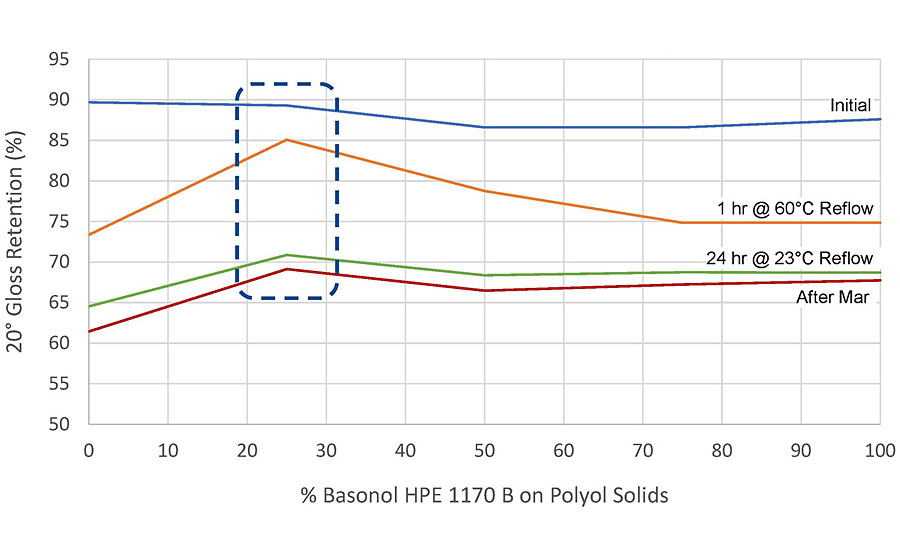

In the scratch resistance test, a formulation containing 25% BASONOL HPE 1170 B with polyol solids exhibited improved scratch resistance and the best reflow behavior, and after 1 hour at 60 °C (140 °F), the coating regained 95% of its initial gloss – a small change invisible to the naked eye.

In the chemical resistance test, MEK double rubs using a 725-g ball peen hammer showed that chemical resistance increases dramatically as more of the polyester is added to the coating system, whereas adding more competitive linear polyesters to a formulation had no effect on chemical resistance. The hyperbranched polymer resins also improved weathering resistance in an accelerated weathering test, and the formula with 25% BASONAL HPE 1170 and light stabilizers maintained almost 100% 60° gloss retention even after 7,000 hours of exposure.

Formulas using the hyperbranched aliphatic polyester polyol reached normal viscosity much slower than other 2K auto refinish clearcoats, demonstrating improved dry time and pot life capabilities. In the curing test, the formulation containing 20% BASONAL HPE 1170 B delivered improved performance at the same cure temperature, along with equal performance at a lower cure temperature versus acrylic-only formulations.

“One of the key properties of this resin is truly its reflow behavior,” says Porzio. “Not only does it decrease the required curing temperatures in a 1K enamel system, but it does this while simultaneously improving scratch resistance.”

In the Mix

BASONOL HPE 1170 B is designed for use as a co-binder, ranging between 5%-30% on total polyol solid for clearcoat and topcoat applications.

“This hyperbranched polyester is meant to be used as a co-polymer, and must be mixed with other acrylic polyols, melamines or other chemistries, as it is very compatible with other chemistries to provide the properties that formulations are looking for,” says Porzio.

The hyperbranched polyester cobinder is compatible with a broad range of resin systems, including high-solids 2K polyurethanes, conventional or medium-solid 2K polyurethanes and 1K amino resin systems.

The Bottom Line

As automakers increasingly look for ways to decrease their impact on the environment while improving production output, new coating technologies can offer an invaluable opportunity to boost process efficiency, introduce cost savings, and reduce VOCs and energy usage while delivering the color and appearance demanded by consumers.

Self-crosslinking technologies can provide fantastic adhesion across a broad range of substrates for basecoats while reducing the required curing temperature and eliminating the need for sensitizers. This offers a safer, simplified and more efficient painting and curing process for automakers, along with improved appearance uniformity.

In the topcoat world, we’re seeing hyperbranched polymer chains make use of highly functional –OH and –COOH groups to reduce viscosity and chain entanglement, extending pot life while offering strong scratch resistance, without sacrificing hardness and chemical resistance.

Although forecasting auto sales projections is always difficult, one thing is clear: technological advances, supply chain disruptions and changing consumer behaviors demand that automakers work on continually improving their processes and materials to promote sustainability, improve quality and remain competitive in an ever-evolving industry.

For more information on JONCRYL U 4501, click here.

For more information on BASONAL HPE 1170 B, click here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!