Anti-Corrosion Finishes for EV-Fastener Applications

yucelyilmaz, Creatas Video+ / Getty Images Plus, via Getty Images

The automotive industry is currently engaged in what can be described as the most significant transformation since its inception in the late nineteenth century. The transition away from fossil-fuel-run combustion engines towards alternative drive trains marks a pivotal step towards achieving a future free of carbon dioxide emissions.

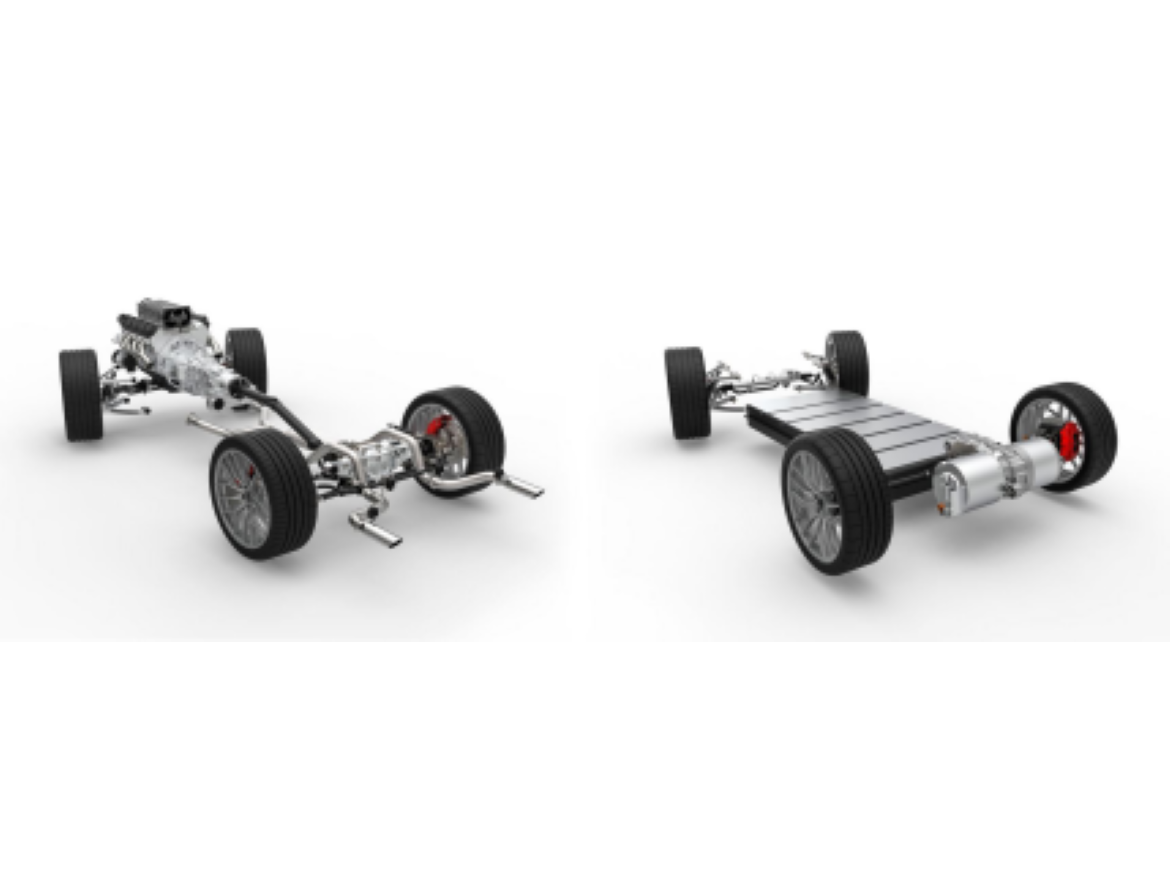

Reflecting on the historical progression of engineering internal combustion engines (ICE), this transition signifies a revolutionary shift in both the manufacturing of automobiles and the operation of their associated supply chains. Nearly every component of powertrain construction is anticipated to undergo a transition (Figure 1).

The current alternative for the mainstream market relies on battery-powered electric engines (BEVs). This approach eliminates the internal combustion engine powertrain, which removes a number of components from the approximately 30,000 elements used in the ICE assembly procedure. In comparison, modern electric vehicles consist of roughly 15,000 components.1

Regardless of the type of powertrain employed, most of the components in both scenarios are fasteners designed to securely hold the various parts together throughout the vehicle's lifespan.

Fasteners are tasked with preventing the connected components from becoming dislodged, while also facilitating easy disassembly for servicing or repairs. This principle applies universally to all fasteners within a car's assembly. It starts with those accommodating minimal demands, such as the screws securing a beverage holder, and extends to those undertaking more intricate responsibilities, such as wheel nuts and bolts. The latter are subjected to the most severe environmental elements and shoulder one of the most safety-critical functions in the vehicle.

In order for fasteners to uphold their commitment of maintaining structural integrity, nothing poses a greater threat to their efficacy during the service life than the accumulation of rust on their surface. This corrosion has the potential to compromise the component's functionality, and in some cases, lead to its destruction.

Given that zinc finishes are recognized as the premier standard for safeguarding fasteners, we need to identify which kind of finish optimally fulfills the combined demands for protection, other functional attributes, and appearance.

When comparing application methods like mechanical plating, metal-rich paints (zinc flake), and electroplating, the standout choice is electroplated finishes. They possess the capability to cater to a spectrum of demands, especially on intricate geometries, all while preserving the consistent mechanical performance of even the smallest finely threaded fasteners.

Electroplated finishes boast exceptional dimensional precision, preventing thread and internal drive-head obstructions, making them suitable for all component sizes. Additionally, fasteners featuring an electroplated zinc-based finish adhere to rigorous cleanliness standards, exhibiting minimal dust generation, especially in automated feeders.

These advantages extend not only to pure zinc-based finishes, but also to electroplated zinc-alloy coatings in particular. Among these, zinc-nickel finishes have emerged as the leading material for electro-deposited anti-corrosion protection in modern fasteners.

Zinc-nickel not only offers significantly enhanced corrosion protection, but also boasts several additional advantages. To name a few, it lends itself to very-low hydrogen embrittlement and excels in situations involving aluminum materials, effectively preventing contact corrosion.2,3

How Does All of This Connect with Powertrain Electrification?

While numerous components in battery-powered electric vehicles differ from those found in internal combustion engine automobiles, there's a consistent need for fasteners.

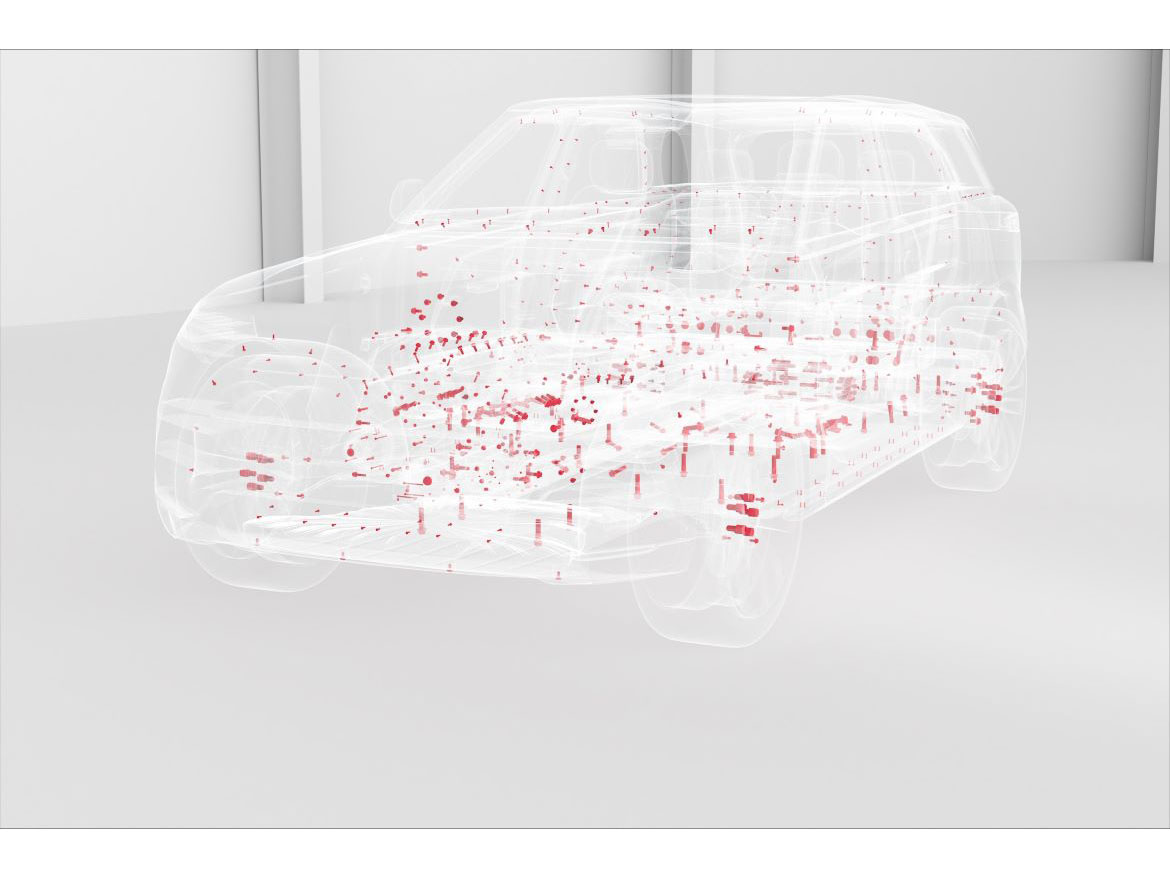

As components shift, EV fasteners will need to change, as well.3 Key elements such as the battery tray, EV engine, and electronics require many smaller-size fasteners while many large fasteners used on the ICE powertrain are removed. Smaller-sized fasteners are also preferred for weight reduction and allow for reduced component size.

Zinc-nickel finishes excel even with these changes, ensuring precision without material build up in threads or internal drives, high cleanliness ensured by the robust, well-adhering coating, minimized hydrogen embrittlement risk (vital for high-strength steel), as well as preventing galvanic corrosion in aluminum assemblies.4

The automotive industry is leveraging these remarkable attributes to their fullest extent today. Embracing the exceptional qualities of zinc-nickel finishes takes on even greater significance as we serve the transformation underway in the requirements of automotive fasteners within the realm of BEVs. And last but not least, zinc-nickel surface finishing can be accomplished while making minimal contributions to the carbon footprint, thus firmly advancing us along the road to a carbon-emission-free future.

For more information, e-mail eliza.garry@829llc.com.

References

1 Whitman, Victor. From Tires to Batteries, Electric Cars also Need Regular Maintenance. Common Electric Car Repairs: A Driver’s Guide. https://blog.wa.aaa.com/electric/common-electric-car-repairs-a-drivers-guide/

2 Brahimi, S. Fundamentals of Hydrogen Embrittlement in Steel Fasteners. Fasteners– Electroplated Coating Systems IBECA 2014.

3 Guide to Fastener Selection for Electrification. Optimas. https://optimas.com/wp-content/uploads/2021/12/Optimas_Guide-to-Fastener-Selection-for-El ectrification.pdf

4 Various automotive standards e.g., VW TL244 2017-06, BMW GS

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!