Paint & Coatings Industry Top Stories

How a New Administration and Congress Will Impact Policy Central to Supply Chain, Business Operations

The Election’s Impact on Chemical Industry

Read More

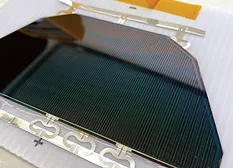

Self-Cleaning Coatings for Space or Earth

Transparent Electrodynamic Dust Shields Usable for Solar Cells

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing