Rethinking Texture Finish

The everyday development work in textured formulations focuses on improving current versions. Tweak a good formulation to be a little better in performance, be a bit more robust or give a slightly higher sales value. PTFE (polytetrafluoroethylene)-based formulations are part of the core portfolio of a powder coating manufacturer. Often, 15–20% of the portfolio is dedicated to fine texture to address this market design demand.

Even when setting up a new formulation, the main decision is utilizing a pure PTFE or a PE/PTFE blend to achieve a deep matte, rough sand texture or a semi-gloss smooth texture. Fine-tune the dosage to achieve the desired visual effect and verify that the physical properties of the formulation are unchanged.

Often, terms like “bulletproof,” “universal” and “narrow specification” are associated with PTFE-based fine-texture formulations to emphasize their standing in the powder coating market and in the mind of the formulator.

With PTFE Considered Part of the PFAS Concern, This is Going to Change

PFAS (per- and polyfluoroalkyl substances) are an environmental and health concern, first raised by EU member states and already acknowledged and confirmed by the European Chemicals Agency (ECHA). Within the REACH registration, a ban or restriction is expected sooner rather than later. Worldwide chemical agencies like the U.S. Environmental Protection Agency (EPA) investigate and restrict PFAS.

As “forever chemicals,” PFAS accumulate in the environment and are distributed via the food chain and water sources. Tests have found increasing concentrations in human blood, indicating a severe health threat.

The use of PTFE in powder coatings for texturing effects is unlikely to have created this severe level of pollution, but the manufacturing process, recycling process and coating degradation due to weathering are nevertheless contributing to the pollution. The widespread use of PFAS in cookware, clothing, firefighting foam and food packaging — to name just a few examples — is the main reason for the expected restriction.

Furthermore, its application in powder coatings is an aesthetic effect, a design choice, giving room for adaptation in taste and allowing technical replacement with an alternative mechanism of action.

As a chemical substance, PTFE has a unique package of properties: It is inert, heat-stable and very non-polar. This allows it to work at low dosages in universal colors and resin compositions. Since not only PTFE, but rather all PFAS substances, are the target of the ban, a change of the chemical nature is needed to fulfill the requirements in the long term.

Rethinking the Textured Formulation is Made Necessary by the Mechanism of Action

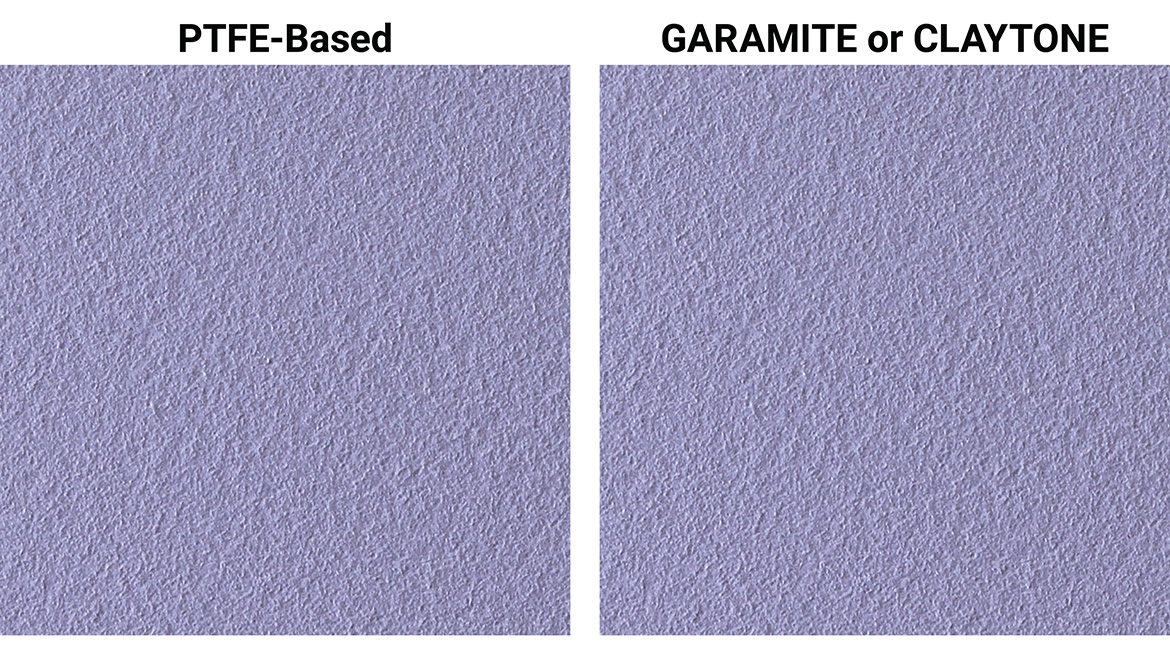

The CLAYTONE and GARAMITE product families by BYK enable the rethinking and realignment of the texturing effect. As they are product families, a specific product type can be selected to meet the specific needs of a formulation regarding gloss level and texture development. As no two textures are the same, this flexibility is a key benefit and valuable tool for the formulator.

A successful PTFE-free texture is not possible without the reformulation and detailed testing of the new approach. The factors and effects that need to be taken into consideration are explained below.

The dosage level of PTFE-free additives is much higher to achieve a texture finish. While PTFE mainly works between 0.3–1.0%, the alternatives need 3.0–5.0% to be effective. But recommendations up to 15% can be found as well. CLAYTONE-HY offers pronounced texture effects at a dosage level from 3.0 to 4.0%.

The dosage range, which is untypically high for an additive, makes the adjustment to the filler ratio mandatory instead of optional. It is recommended to reduce the filler content by the same amount by which the PTFE-free additive is increased. By using this principle, the pigment-binder ratio is not changed, allowing the physical properties of the system to remain the same. If no rebalancing takes place, the reduced binder content would lead to, e.g., reduced mechanical resistance. Nevertheless, practical experiences strongly indicate a validation of mechanical properties as highly important.

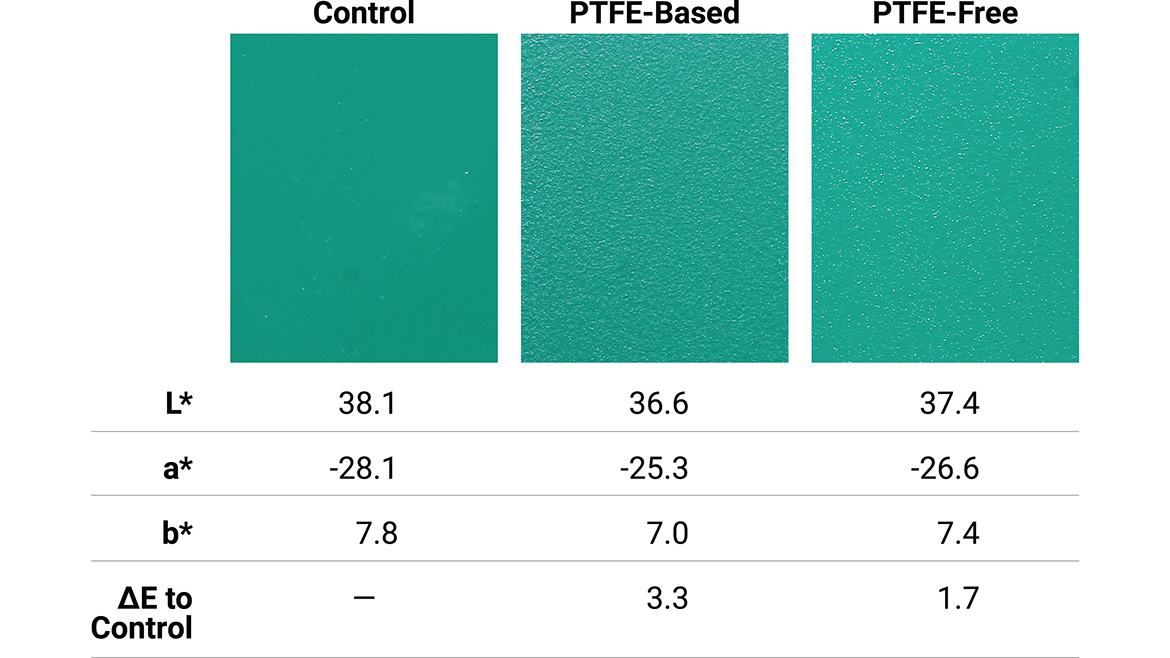

As the PTFE-based formulation is typically used as a color standard to be matched by the alternative additives, the impression may arise that all alternatives have a tendency toward a yellow color. However, the PTFE itself actually shifts the color toward blue. This becomes obvious when comparing the color of a control (untextured surface) to the PTFE-based and PTFE-free additives. While the control and PTFE-free coatings show the same or similar color, the actual color shift is in the PTFE-based panel.

Color matching and slight adjustment of the pigmentation to a bluish shade is necessary in all formulations replacing PTFE.

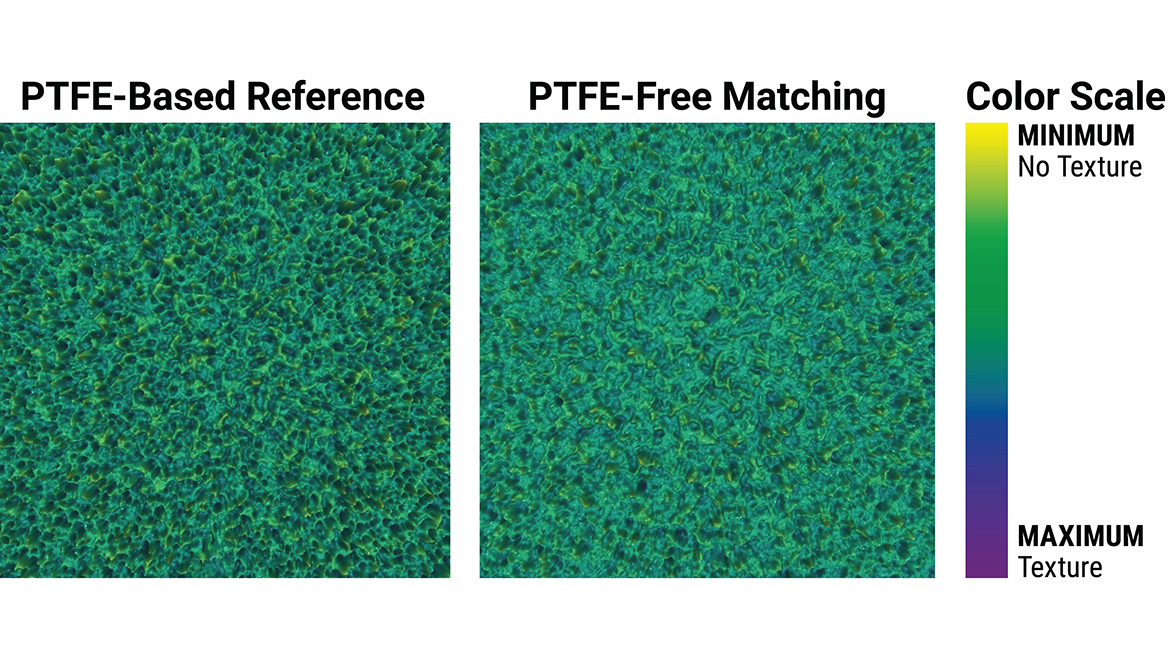

A challenge in the rethinking process is the difficulty in describing a texture. The visual impression is always a combination between gloss level and texture development. The same texture with two slightly different gloss levels can be easily differentiated by the trained eye. For this reason, defining the texture by gloss level alone is not sufficient. In order to objectify the texture description, BYK utilizes the BYK spectro2profiler to generate 3D scans of the topography of the texture. In the case of gloss levels and colors that are very similar, the measurement makes it possible to closely match a PTFE texture with the right selection and combination of additives.

Nevertheless, the homogeneity of the effect on the surface, in particular close to the edges, still needs to be judged by a trained eye. Differences in gloss depending on the view angle or any sparkling can also just be visually evaluated. These properties are typically not specified but differentiate almost identical textures from each other. The formulator has to decide what is acceptable and what is not.

On the one hand, this is a big challenge and requires a lot of effort to set the boundaries for more aspects than just gloss level and texture. On the other hand, it does allow a wider range of visual impressions within the specification.

After overcoming the challenge of defining the texture in detail, the touch of the surface is the next relevant property to consider. This property is even more difficult to describe and judge, especially because there is no “right” or “wrong” touch. In some cases, a very rough, sandpaper-like feeling is required, while other application areas require a smooth, softer haptic. The main roughness is determined by the pigment selection but can be adjusted with a choice of additives like CERAFLOUR 950. This wax-based product reduces the roughness without interfering with the texture development.

After these five selection and definition steps, visual matching of the PTFE texture is completed successfully. Due to the change from an inert substance to reactive components as mode of action, a broader evaluation of the formulation is highly recommended.

PTFE is a heat-stable, inert material. Its white color can withstand high temperatures — higher temperatures than curing conditions in powder coating. Any organic-based or modified additive will be challenged in this area. A practical test is to subject the additive to heat stress, e.g., 30 min at 200 °C, and evaluate the change in color of the pure substance.

More precisely, a coated white panel is subjected to overstoving and then delta b* is measured. Due to the high dosage levels of all PTFE-free alternatives, a yellowing additive will show in light colors. However, the practical test can provide indications to help in a preselection.

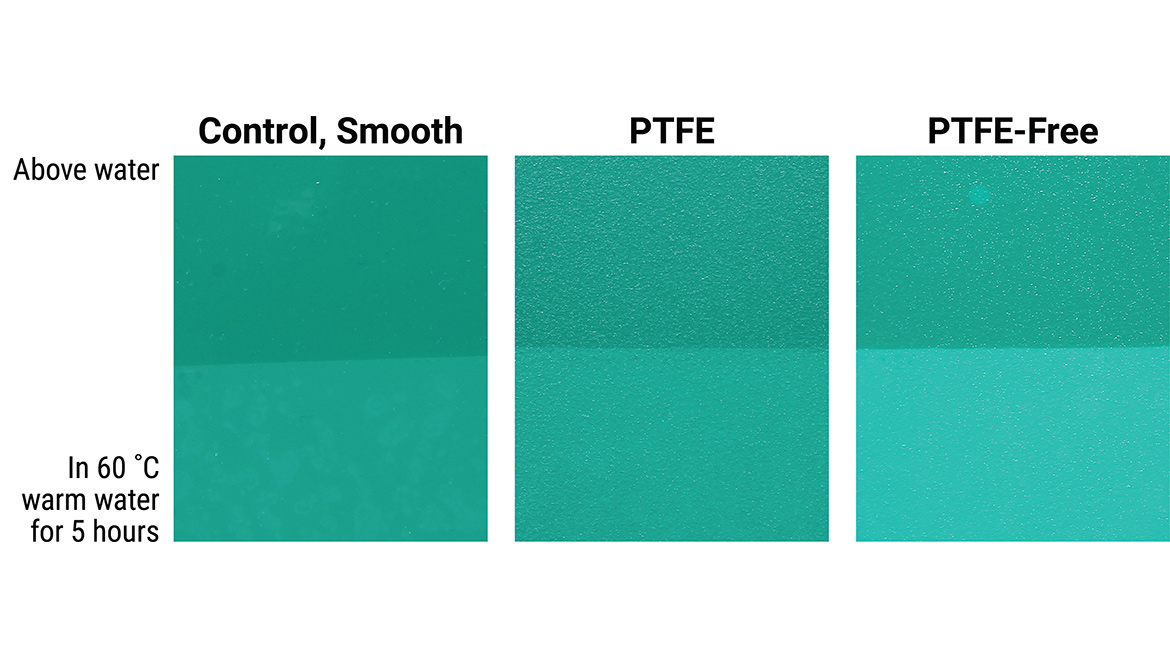

Multiple application fields require low sensitivity to water. For example, resistance to blanching — an undesired paling in color due to immersion in 60 °C warm water — is a common requirement. PTFE, as its use in rain jackets and outdoor wear already indicates, did provide a good level of resistance. With the PTFE-free alternatives, a more polar and therefore more hydrophilic component is introduced to the formulation in a relevant amount. Practical tests need to be carried out, verifying if the performance still fulfills the needs of the application. If not, an adjustment in the resin must be considered.

Texture finishes are sold not only in solid color shades. The addition of effect pigments to provide either a metallic effect or a fine sparkle is also a desired design option. To achieve high quality, a bonding process is needed. The quality of bonding is judged by changes in color and visual texture by recycling the powder coating in a cyclone, comparing the virgin powder coating to the recycled powder coating. As negative control, a dry blend can be utilized. The difference in chemical nature of the PTFE-free additives can influence the bonding process. In cooperation with ECKART, CLAYTONE-HY was evaluated in terms of bonding properties, reaching high-quality bonding and achieving the desired surface.

To summarize, a PTFE-free texture can be achieved with the available alternatives. The choice of multiple additive types and their combinations offers the possibility to match established textures in color, gloss level and visual impression. The chemical nature and needed dosage range make it necessary to rethink the formulation; small adjustments are not sufficient. The core criteria of binder type, pigment-binder ratio and pigmentation need to be carefully monitored and adjusted. Visual matching alone of the texture is not enough. Coating properties such as tendency toward yellowing, water resistance and bonding quality must be evaluated and not just visually verified since changes are expected.

Learn more about powder coatings technologies.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!